Welcome to BAOLAN EP INC.

24-Hour Hotline

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Sewage waste gas treatment

——————————————— ◆ Exhaust gas analysis ◆ ———————————————

Source of sewage and waste gas

(1) the peculiar smell waste gas of the sewage treatment station mainly comes from the grid room and anaerobic organism of sewage pretreatment, the latter has a large amount of peculiar smell waste gas and a pungent taste.

(2) in the process of anaerobic reaction of wastewater through anaerobic biological process, odor waste gas such as small molecule hydrocarbon, methane, hydrogen sulfide, ammonia, methylmercaptan and a small amount of volatile organic waste gas in wastewater are produced. These components not only stimulate the taste, but also have toxicity.

Composition of waste water and gas

(1) hydrogen sulfide

Colorless, stinky egg odor gas, soluble in water and ethanol, flammable, strong nerve poison, serious damage to the central nervous system, respiratory system and myocardial. Inflammable, it can cause combustion and explosion in case of open fire and high heat.

(2) ammonia

The irritating odor is colorless gas, which is very soluble in water. Ammonia water is corrosive to metals. Ammonia poisoning will inhibit the central nervous system, and there will be muscle random excitation, angle bow reflex and convulsion.

(3) methanethiol

Inflammable. Steam and air can form explosive mixture. In case of heat source, open fire, etc., there is a risk of combustion and explosion. It reacts with water and steam to produce toxic and flammable gas. After absorption, it can cause headache, nausea and different degrees of anesthesia. High concentration inhalation can cause respiratory paralysis and death.

——————————————— ◆ Technological design ◆ ———————————————

Process Brief

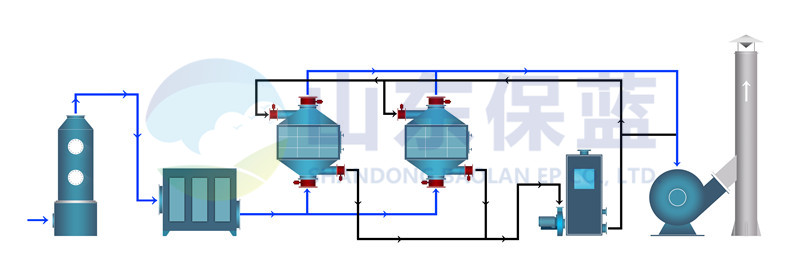

(1) after the dust and granular substances are removed by pretreatment, the waste gas is sent to the activated carbon adsorber I and II. When the activated carbon adsorber I is close to saturation, the treatment gas is automatically switched to the activated carbon adsorber II (the adsorption operation of the activated carbon adsorber I stops), and then the activated carbon adsorber I is desorbed and desorbed with hot gas flow to desorb the organic matters from the activated carbon. In the desorption process, the organic waste gas has been concentrated, and the concentration has increased dozens of times than before, reaching more than 2000 ppm. The concentrated waste gas is sent to the catalytic decomposition unit, and finally discharged as CO2 and H2O.

(2) after the desorption, the activated carbon adsorber I will enter the standby state. When the activated carbon adsorber II is close to saturation, the system will switch back automatically, and at the same time, the activated carbon adsorber II will be desorbed and desorbed, so it will work in cycle.

(3) when the concentration of organic waste gas reaches more than 2000 ppm, the catalytic bed can maintain spontaneous combustion without external heating. The scheme not only greatly saves energy consumption, but also reduces equipment investment because the treatment capacity of catalytic decomposer only needs 1 / 5 of the original waste gas treatment capacity (60000m3 / h). This scheme is not only suitable for continuous work, but also suitable for intermittent work.

——————————————— ◆ Cooperation ◆ ———————————————

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province