- Carbon Capture Utilization

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Tel: +86-135-8959-1050

E-mail: [email protected]

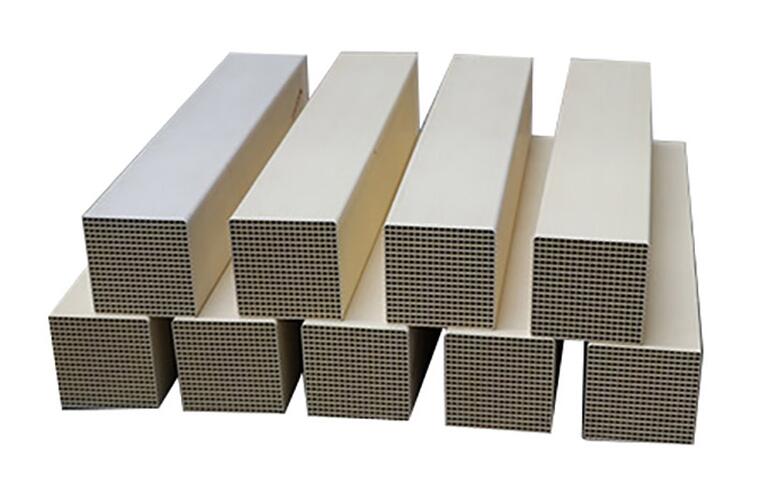

Honeycomb Ceramic Catalyst

ULTRA-LOW TEMPERATURE SCR DENITRATION CATALYST

The ultra-low temperature denitrification catalyst developed by the company has good denitrification performance under low sulfur and dust conditions at 150-180°C in the ultra-low temperature section. The denitrification efficiency can reach more than 90%. It is widely used in Vaiours industries such as natural gas boilers and kilns.

LOW TEMPERATURE SCR DENITRATION CATALYST

The company's self-developed low-temperature denitration catalyst adopts advanced production technology. The catalyst has very good denitration performance in the low temperature section (180-280 °C), it can process high concentration of nitrogen oxides, and the denitration efficiency is over 95%. Low-temperature denitration catalysts are widely used in coking plants, sintering machines, small industrial boilers, industrial furnaces, glass and other industries.

MEDIUM TEMPERATURE SCR DENITRATION CATALYST

This type adopts a front-end hardening process, increase the wear-resistant coating and maintain a long mechanical life. The raw material is made of high quality anatase titanium dioxide with large specific surface area. It is optimized for the flue gas environment of various industries and has strong anti-poisoning ability. The product design can be carried out for different flue gas conditions, with strong pertinence and excellent product performance. Widely used in power plant boilers, industrial boilers and other industries, to adapt to temperature range of 280-420°C.

HIGH TEMPERATURE SCR DENITRATION CATALYST

This type adopts international advanced technology and high-quality cordierite catalyst carrier. Coating composite molecular sieve catalyst, to improve the activity and stability of the catalyst at high temperature. It can be widely used in 300-550°C working conditions, and can be customized according to different industry conditions. It is commonly used in various high-temperature flue gas fields such as gas kiln and diesel engine.

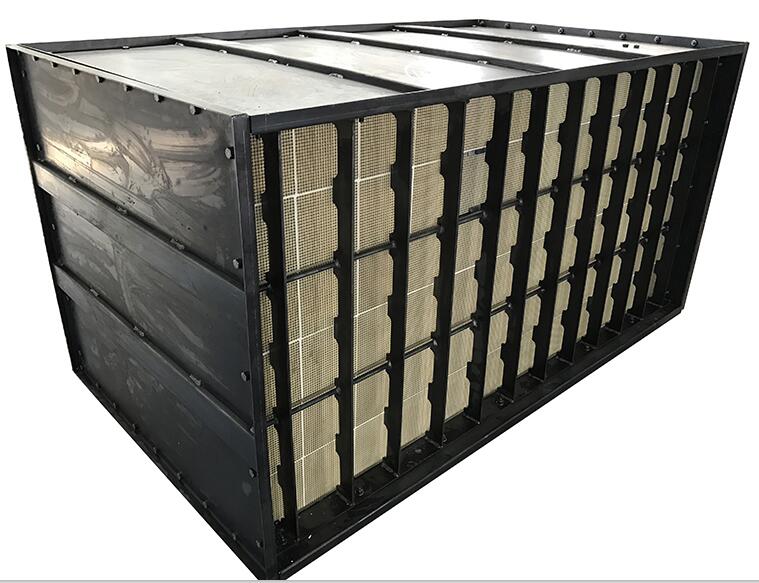

Product Description

Advantage

1. It is relatively independent of the exhaust gas body, and does not change the original material and heat balance;

2. High efficient sulfur and water resistance, reducing the one-time investment and operation cost of denitration system;

3. High efficiency dust resistance, reduce the investment of front-end pre dedusting system;

4. SCR reactor is flexible and suitable for various working conditions;

5. The whole SCR process temperature range is wide, suitable for 180 ~ 300 degrees; 6. Efficiency index: denitration efficiency ≥ 85%, catalyst activity efficiency ≥ 95%.

Application

It is widely used inthermal power plants, coal-fired power plants, waste incineration plants, steel plants, fertilizer plants, nitric acid plants, cement plants, petrochemical chemical plants and other all industrial which need to reduce the NOx emissions, also used in diesel engines tail gas treatment etc.

Honeycomb Ceramic Catalyst Remark

◇ in case of leakage upstream of catalyst, it is necessary to avoid water entering into catalyst or forming water drop on its surface, otherwise the performance of catalyst will be reduced.

◇ the catalyst is designed according to the fuel specified in the technical specifications. If the fuel changes, the performance of the catalyst will be affected.

◇ during the operation of the equipment, excessive vibration of the catalyst bed shall be avoided as far as possible, otherwise, the catalyst will be damaged such as crack.

Services Quality first, service first

Shandong baolan in order to guarantee product quality, the whole cube with wooden pallets, forklift loading and unloading to reduce damage of manual handling.

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province