Welcome to BAOLAN EP INC.

24-Hour Hotline

- Carbon Capture Utilization

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

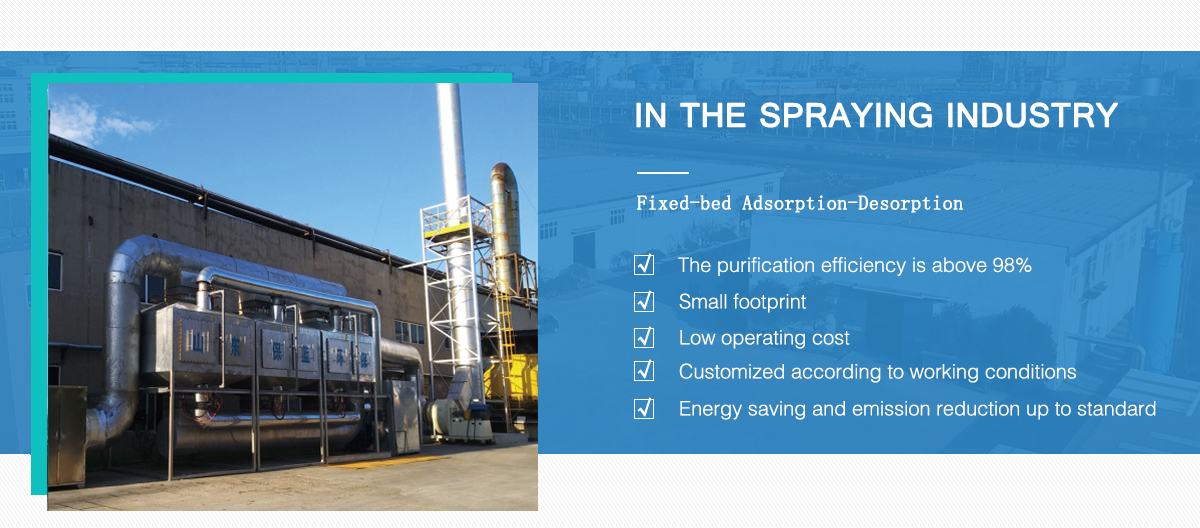

Fixed-bed Adsorption

Adsorption-desorption

Introduction Molecular sieve adsorption-desorption refers to the use of solid molecular sieve (molecular sieve currently includes: activated carbon molecular sieve and zeolite molecular sieve), adsorption of pollutants in industrial waste gas, according to different components of waste gas, select the appropriate molecular sieve. When the molecular sieve is saturated, the pollutants will be desorbed. The catalytic combustion technology is used to oxidize the organics in the industrial waste gas into carbon dioxide and water, so as to achieve the purpose of purification.

1. high efficiency of adsorption and desorption. Using high quality molecular sieve material, the purification effect is good, and the wind speed resistance is small. The treatment effect can reach the first level standard specified in gb16279-1996 integrated emission standard of air pollutants.

2. small size, simple structure, convenient transportation, saving installation space and installation procedures. It has changed the traditional organic waste gas purification system, which covers a large area, has a complex installation, is easy to be limited by the site and space, etc.; the modular integration of all processing units has avoided the complex installation procedures, greatly saved the space utilization, and has the advantage of ready to install and ready to use.

3. high degree of automation. It can detect the concentration of waste gas in real time and use catalytic combustion to desorb and purify the adsorption unit in time, which not only saves the manpower cost of purification, but also ensures the desorbing effect and greatly improves the desorbing efficiency.

4. two or more adsorption systems are regenerated alternately, which not only ensures the continuity of production, but also reduces the operating cost.

It has the advantages of low air resistance, low reaction temperature and high purification effect.

● Exhaust treatment of various spray paint workshops (automobile manufacturing, shipbuilding, bicycle manufacturing, aircraft manufacturing, metal products, etc.)

● Exhaust treatment of various printing workshops (gravure printing, printing of building and decoration materials, various other printing processes)

● Exhaust treatment for aluminum profile production and coating process

● Exhaust treatment in the manufacturing process of various electronic products

● Exhaust treatment of semiconductor integrated circuits and liquid crystal display (LCD) manufacturing processes

● Exhaust treatment during lithium ion battery manufacturing (electrode formation process, electrolyte filling process)

● Exhaust treatment in the production of resin, rubber, tires and other products

● Disposal of volatile organic compounds from dispersive sources such as car repair shops and clothing dry cleaners

● Exhaust gas treatment containing impurities such as nitrogen, sulfur, and chlorine in the exhaust gas

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province