Welcome to BAOLAN EP INC.

24-Hour Hotline

- Carbon Capture Utilization

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Chemical waste gas treatment

——————————————— ◆ Exhaust gas analysis ◆ ———————————————

Chemical waste gas composition

The waste gas produced by chemical plants is generally divided into three categories:

(1) sulfur compounds, such as hydrogen sulfide, mercaptan, dimethyl sulfur, thioether and heterocyclic sulfur compounds;

(2) nitrogen compounds, such as ammonia, amines, nitriles, nitro compounds and nitrogen heterocyclic compounds;

(3) carbon, hydrogen or compounds composed of carbon, hydrogen and oxygen (lower alcohols, aldehydes, fatty acids, etc.).

Among them, the eight odor substances that have great influence on human body are hydrogen sulfide, ammonia, trimethylamine, methylmercaptan, methylsulfide, carbon disulfide, styrene and dimethyldisulfide. And what we usually refer to as odor gas is the gas with odor diffused in the air.

Characteristics of chemical waste gas

1. There are many inflammable and explosive gases.

For example, ketones, aldehydes with low boiling point, and unsaturated hydrocarbons that are easy to polymerize, a large number of flammable and explosive gases are easy to cause fire and explosion accidents and great harm if appropriate measures are not taken.

2. Most of the emissions are irritant or corrosive.

For example, sulfur dioxide, nitrogen oxide, chlorine, hydrogen fluoride and other gases are irritant or corrosive, especially sulfur dioxide emissions are the largest. Sulfur dioxide gas directly damages human health, corrodes the surface of metals, buildings and sculptures, and is easy to oxidize into sulfate and land on the ground, polluting soil, forests, rivers and lakes.

3. There are many kinds of floating particles in the waste gas, causing great harm.

The floating particles excluded from chemical production include dust, flue gas, acid mist, etc. there are many kinds, which do great harm to the environment. Especially when the floating particles and harmful gases exist at the same time, they can produce synergistic effect, which is more serious to human beings.

——————————————— ◆ Technological design ◆ ———————————————

Process Brief

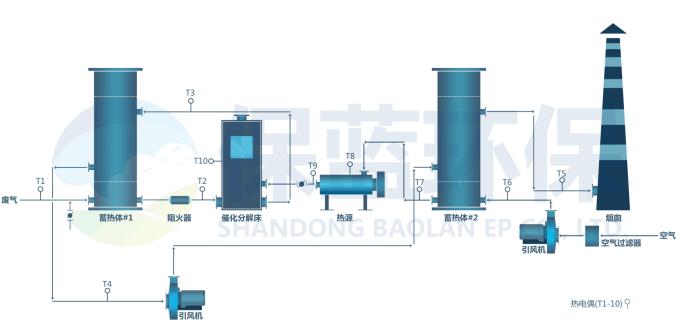

(1) exhaust gas passes through heat exchanger I, and the temperature is increased from 10 ℃ to 150 ℃. The heat source is high temperature gas (300-350 ℃) after reaction of catalytic decomposition unit. Temperature recovery and utilization, reduce the operating cost of the system;

(2) the preheated gas enters into the catalytic decomposition device after passing through the flame arrester, and is mixed with high temperature air (480 ℃) in the mixing chamber at the bottom of the device to raise the temperature of exhaust gas to about 300 ℃ to reach the catalytic reaction temperature, and then the air flow rises to the catalytic reaction area to react on the catalyst surface, decompose into CO2 and H2O, and finally discharge at the bottom outlet;

(3) under the action of induced draft fan, the high temperature gas passes through heat exchanger I, the initial exhaust gas is heated up through indirect heat exchange, and then comes out from heat exchanger I, and enters into heat exchanger II through induced draft fan. As a heat source, the air needs to be heated again for preheating, so that the air is heated from normal temperature to about 100 ℃, the temperature is recycled, the system operation cost is reduced, and then enters the chimney Discharge up to standard;

(4) the preheated air enters into the air heater. Under the action of the electric heating rod, the air is heated from 100 ℃ to 480 ℃, and then enters into the catalytic reaction device to mix with the waste gas to improve the temperature of the waste gas.

——————————————— ◆ Cooperation ◆ ———————————————

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province