Welcome to BAOLAN EP INC.

24-Hour Hotline

- Carbon Capture Utilization

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Printing exhaust gas treatment

——————————————— ◆ Exhaust gas analysis ◆ ———————————————

Printing waste gas source

Printing waste gas is mainly the waste gas of printing ink and the gas of gasoline volatilization used to clean the ink stick.

(1) a small amount of printing ink waste gas volatilized during printing, which is mainly composed of low-grade hydrocarbons and does not contain benzene, toluene and other harmful components. The output is calculated as 10% of the ink consumption, and the emission is 0.3t/a;

(2) clean up the volatile exhaust gas from the ink stick and the gasoline used in the printing plate. The volatilization of gasoline is calculated by the total amount of non methane hydrocarbon. The consumption is only 0.6 T / A, the volatilization is calculated as 5%, and the emission is 0.03 T / A. The second level standard of gb16297-96 comprehensive emission standard of air pollutants shall be implemented for the exhaust gas emission of the project (maximum allowable emission concentration of non methane total hydrocarbon: 120mg / m3, emission rate: 10kg / h (15m exhaust funnel)).

Printing waste gas characteristics

1. A small amount of ink waste gas volatilized during printing, which is mainly composed of low-grade hydrocarbons and does not contain benzene, toluene and other harmful components. The generated amount is calculated as 10% of the ink consumption. Generally, the waste gas generated by ink is mainly the non methane total hydrocarbon organics produced by the volatilization of ink diluent.

2. The dust in the ink shall be controlled by carbon black as the pollution factor. PM10 shall be considered, and attention shall be paid to the treatment measures. If it is oily ink, it can be considered that in the process of use, all the organic solvents volatilize, only in a period of time.

3. Compared with solvent based inks, there are few organic solvents in offset inks, so the volatilization of organic solvents is less and the environmental pollution is less. Most of the offset paper inks are dried by oxidation conjunctiva or UV inks are dried by UV curing.

——————————————— ◆ Technological design ◆ ———————————————

Process Brief

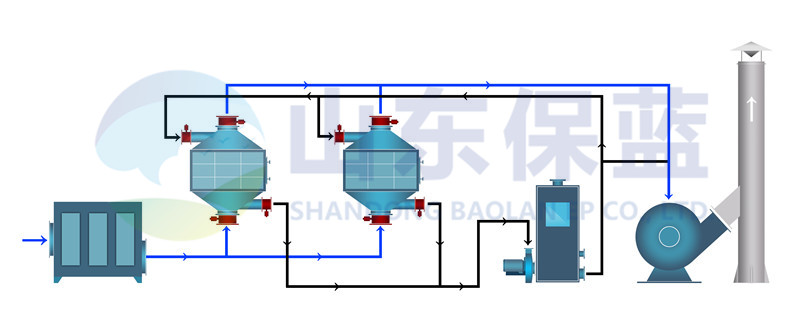

(1) after the dust and granular substances are removed by pretreatment, the waste gas is sent to the activated carbon adsorber I and II. When the activated carbon adsorber I is close to saturation, the treatment gas is automatically switched to the activated carbon adsorber II (the adsorption operation of the activated carbon adsorber I stops), and then the activated carbon adsorber I is desorbed and desorbed with hot gas flow to desorb the organic matters from the activated carbon. In the desorption process, the organic waste gas has been concentrated, and the concentration has increased dozens of times than before, reaching more than 2000 ppm. The concentrated waste gas is sent to the catalytic decomposition unit, and finally discharged as CO2 and H2O.

(2) after the desorption, the activated carbon adsorber I will enter the standby state. When the activated carbon adsorber II is close to saturation, the system will switch back automatically, and at the same time, the activated carbon adsorber II will be desorbed and desorbed, so it will work in cycle.

(3) when the concentration of organic waste gas reaches more than 2000 ppm, the catalytic bed can maintain spontaneous combustion without external heating. The scheme not only greatly saves energy consumption, but also reduces equipment investment because the treatment capacity of catalytic decomposer only needs 1 / 5 of the original waste gas treatment capacity (60000m3 / h). This scheme is not only suitable for continuous work, but also suitable for intermittent work.

——————————————— ◆ Cooperation ◆ ———————————————

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province