Welcome to BAOLAN EP INC.

24-Hour Hotline

- Carbon Capture Utilization

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Electroplating waste gas treat

——————————————— ◆ Exhaust gas analysis ◆ ———————————————

Electroplating waste gas source

(1) cyanide containing waste gas, chromium containing waste gas, dust containing waste gas, etc. are produced in the electroplating production process, and acid mist will be produced in the pickling process and the stripping process (nitric acid, sulfuric acid, hydrochloric acid).

(2) some electroplating waste gas is colorless and tasteless, causing long-term and chronic damage to respiratory tract. After gradual accumulation, the content exceeds the limit, which will lead to bronchitis, bronchial asthma, lung cancer, liver cancer and other diseases. However, hydrogen chloride and acid-base mist discharged by electroplating process will cause irritation to human eyes and skin, as well as red eye disease and dermatitis. These waste gases not only affect the working environment and human health of the workshop, but also pollute the surrounding environment. So we need to treat the waste gas.

Composition of electroplating waste gas

The main types of electroplating waste gas are hydrogen chloride, chromic acid mist, sulfuric acid mist, nitrogen oxide, hydrogen cyanide and fluoride. In addition, there are some dust gas, organic waste gas and alkaline gas

(1) acid cleaning: hydrogen chloride, hydrogen fluoride and other gases, as well as phosphoric acid, sulfuric acid and other acid mist;

(2) chemical oil removal: alkali mist such as sodium hydroxide;

(3) electroplating: chromium containing waste gas of chromium plating, cyanide containing waste gas (a small amount) of cyanide containing electroplating, alkali mist of alkaline electroplating, etc.

——————————————— ◆ Technological design ◆ ———————————————

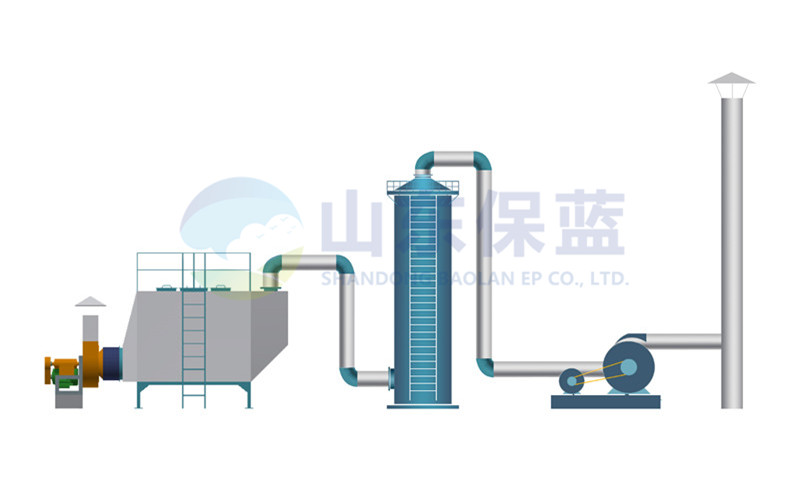

(1) the waste gas of chromic acid mist volatilized from chrome plating tank and stripping tank is collected through the side suction hood provided for the electroplating production line. The acid mist in the tank is collected to the main road air duct through the air ducts of each branch, and then enters the complex and heavy metal purification bed for preliminary recovery of chromic acid (the recovered chromic acid from the recycler can be reused for the chromium plating tank solution of the production line);

(2) then enter the packing spray tower for neutralization and absorption by the dilute alkali solution, and the tail gas after reaching the standard is finally discharged at a height of not less than 15m from the ground through the exhaust funnel.

——————————————— ◆ Cooperation ◆ ———————————————

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province