Welcome to BAOLAN EP INC.

24-Hour Hotline

- Carbon Capture Utilization

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Rubber waste gas treatment

——————————————— ◆ Exhaust gas analysis ◆ ———————————————

Harm of rubber waste gas

Most of the waste gas pollutants in the rubber waste gas come from the process of raw material polymerization and heat treatment in the rubber production line, which may contain a large number of organic waste gas and flue gas such as styrene, benzene, xylene, butanone, aldehyde, sulfide, nitrogen oxide, etc., and spread to the whole workshop and the surrounding area along with a certain temperature, which is a relatively serious waste gas.

Rubber waste gas and rubber vulcanization flue gas are harmful. The components of the waste gas contain odorous substances, which float away with the wind direction and stay in the air for a long time. Cause various adverse effects. Therefore, effective collection and purification are needed to ensure the good production and operation of the enterprise, improve the workshop and plant environment, and meet the national environmental protection requirements.

Composition of rubber waste gas

The main components of rubber waste gas are tar, odor gas and non methane total hydrocarbon. The odor components of rubber waste gas are complex and variable, which can be roughly divided into five categories:

(1) sulfur compounds: such as H2S, SO2 and mercaptan;

(2) dust: such as carbon black;

(3) compounds containing chlorine: such as amides and indoles;

(4) hydrocarbon: such as alkane, olefin, hydrocarbon and aromatic hydrocarbon;

(5) organic matters containing oxygen, such as alcohol, phenol, aldehyde, ketone, organic acid, etc.

——————————————— ◆ Technological design ◆ ———————————————

Process Brief

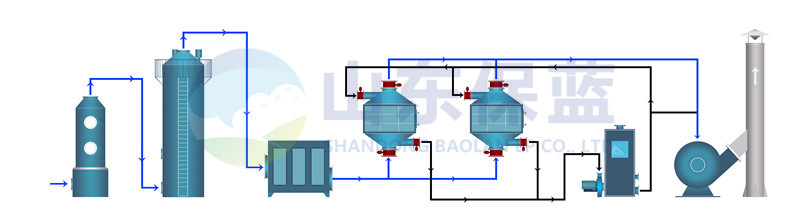

(1) the waste gas collected by the gas collecting hood is led into the purification tower by the air pipe, and the gas and water in the packing layer are fully contacted, absorbed and neutralized by the gas-liquid two-phase. The waste gas enters the next process after purification.

(2) the treated waste gas enters into the ionization trapper. When the flue gas passes through, the dust and tar in the flue gas are ionized under the action of electric charge, moving towards the charged metal wire and pipe wall, and losing the electric charge. Under the action of gravity, the waste gas falls to the bottom of the ionization trapper and flows out, so that the pollutants can be degraded and removed.

(3) the captured waste gas enters into the deep purification system. When the activated carbon adsorber is close to saturation, the hot gas flow is used to desorb the activated carbon adsorber, and the organics are desorbed from the activated carbon. In the desorption process, the organic waste gas has been concentrated, and the concentration is dozens of times higher than the original, reaching more than 2000 ppm. The concentrated waste gas is sent to the catalytic decomposition unit, and finally becomes CO2 and H2O. After deep purification, it is discharged through the fan chimney.

——————————————— ◆ Cooperation ◆ ———————————————

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province