- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Tel: +86-135-8959-1050

+86-182-5337-2878

Fax: +86-0533-3585998

E-mail: [email protected]

The company attaches great importance to environmental protection while vigorously improving the economic benefits of the enterprise and paying attention to product quality. The company's leaders, in line with the principle of creating a good production and living environment for the employees and the surrounding residents, collect and process the gas generated in the operation process and completely eliminate the hidden dangers of the enterprise's development. Entrusted by the company, shandong baolan environmental protection engineering co., LTD. Based on the design principle of mature and reliable technology, reasonable overall layout, convenient operation and management, and low processing cost, we have compiled this scheme.

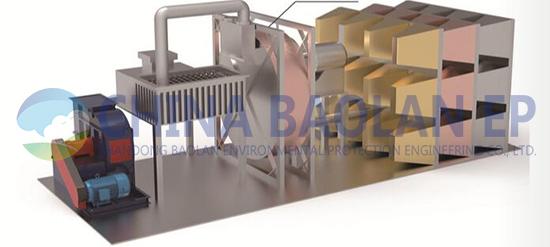

The main structure of the zeolite rotor is a rotating wheel filled with an adsorbent, which is divided into three regions, namely an adsorption region, a regeneration region, and a cooling region. The vocs is introduced into the adsorption area through a blower, and the vocs pollutants therein are adsorbed, and the exhaust gas is purified and discharged. Subsequently, the adsorbent was rotated to the regeneration-zone, and during contact with the high-temperature air, VOCS was desorbed and flowed out with the regeneration air, and the adsorbent was regenerated. The regenerated adsorbent is first cooled through the cooling zone, and then rotated to the adsorption zone to re-adsorb. As the rotor rotates, the adsorbent periodically adsorbs, desorbs, and cools to achieve purification of organic waste gas.

FAX:+86-0533-3585998

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

| Your Name *: | |

| Email *: | |

| Telephone: | |

| Inquiry: |

Copyright © 2014-2021 BAOLAN EP INC.

Telephone: +86-135-8959-1050 +86-182-5337-2878 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province