- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact us

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

+86-182-5337-2878

Fax: +86-0533-3585998

E-mail: [email protected]

Tel: +86-135-8959-1050

+86-182-5337-2878

Fax: +86-0533-3585998

E-mail: [email protected]

Cases

> Cases >

Grain and oil plant flue gas de-white

At present, the business of Baolan enterprise users mainly covers three major business areas:

Field 1: Electromagnetic De-white;

Field 2: Dedusting, desulfurization and denitrification;

Field 3: VOCS organic waste gas treatment.

TEL:+86-135-8959-1050

Product introduction

The company attaches great importance to environmental protection while vigorously improving the economic benefits of the enterprise and paying attention to product quality. In line with the principle of creating a good production and living environment for the employees and the surrounding residents, the company leaders plan to collect and deal with the white smoke generated in the operation process, so as to eliminate the hidden dangers of the enterprise's development. Entrusted by the company, shandong baolan environmental protection engineering co., LTD. In line with the design principle of mature and reliable technology, reasonable overall layout, convenient operation and management, and low processing cost, we compiled the scheme.

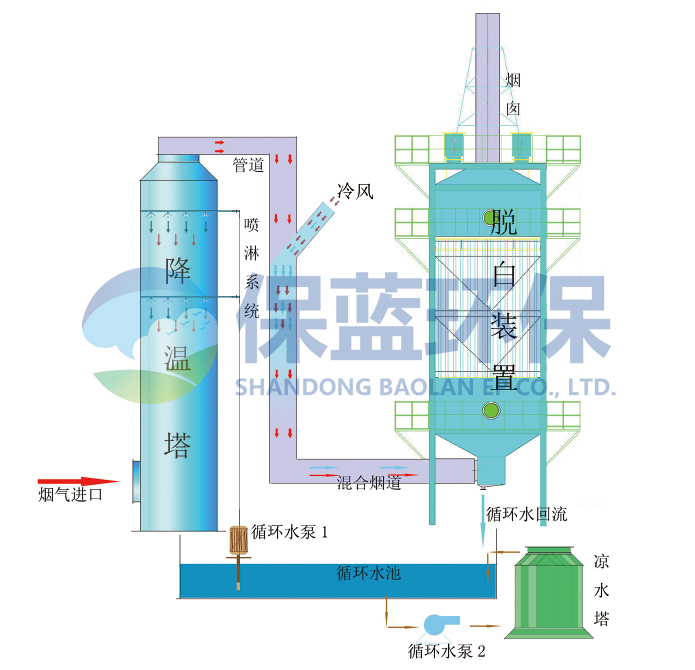

Introduction to the process:

(1) the main components of white smoke are small droplets formed by condensation of water and gas, which are also doped with other components. Electromagnetic bleaching device is adopted in the purification process.

(2) the upper discharge desulfurization tower of flue gas temperature is higher, white set of spray cooling in a flue, white smoke into the spray cooling area, set up two pumps, circulating cistern in the cold water circulating cistern via 1 spray pump to spray section of the flue, flue gas gas liquid two phase reverse contact with low temperature cold water absorption reaction, make the flue gas temperature is reduced, which will be in flue gas water vapor condense into liquid droplets. Since the circulating water absorbs the heat in the flue gas through the spray area, the temperature rises, so a cooling tower is added to cool the water in the circulating pool.

(3) after the cool white smoke into the white device in electromagnetic release, when the flue gas by flue gas moisture of the material under the action of electromagnetic field, directional move, move to the cathode, the formation of liquid film, under the action of gravity automatic downflow, from electromagnetic release white at the bottom of the equipment, to the circular pool, net gas from to take off the white upper system equipment, at the same time in the purification of moisture also synchronous implementation of dust, acid mist co-treating removal, guarantee the equipment purification efficiency is above 98%, final discharge data is close to zero.

(1) the main components of white smoke are small droplets formed by condensation of water and gas, which are also doped with other components. Electromagnetic bleaching device is adopted in the purification process.

(2) the upper discharge desulfurization tower of flue gas temperature is higher, white set of spray cooling in a flue, white smoke into the spray cooling area, set up two pumps, circulating cistern in the cold water circulating cistern via 1 spray pump to spray section of the flue, flue gas gas liquid two phase reverse contact with low temperature cold water absorption reaction, make the flue gas temperature is reduced, which will be in flue gas water vapor condense into liquid droplets. Since the circulating water absorbs the heat in the flue gas through the spray area, the temperature rises, so a cooling tower is added to cool the water in the circulating pool.

(3) after the cool white smoke into the white device in electromagnetic release, when the flue gas by flue gas moisture of the material under the action of electromagnetic field, directional move, move to the cathode, the formation of liquid film, under the action of gravity automatic downflow, from electromagnetic release white at the bottom of the equipment, to the circular pool, net gas from to take off the white upper system equipment, at the same time in the purification of moisture also synchronous implementation of dust, acid mist co-treating removal, guarantee the equipment purification efficiency is above 98%, final discharge data is close to zero.

◆ High efficiency. The impurities and white smoke are captured by electromagnetic field with high efficiency and good effect.

◆ The floor space is small. Blue electromagnetic whitening system has simple structure, reasonable layout and small area.

◆ Wide application. Blue - preserving electromagnetic bleaching system is suitable for flue gas bleaching in thermal power plants and chemical plants.

◆ Low operation cost. The electromagnetic descaling system can remove impurities such as tar, dust and water mist to achieve the double effect of material recovery and gas purification and save cost.

◆ The floor space is small. Blue electromagnetic whitening system has simple structure, reasonable layout and small area.

◆ Wide application. Blue - preserving electromagnetic bleaching system is suitable for flue gas bleaching in thermal power plants and chemical plants.

◆ Low operation cost. The electromagnetic descaling system can remove impurities such as tar, dust and water mist to achieve the double effect of material recovery and gas purification and save cost.

Case pictures

CONTACT

BAOLAN EP INC.

TEL:+86-135-8959-1050

FAX:+86-0533-3585998

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

FAX:+86-0533-3585998

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Procurement

| Your Name *: | |

| Email *: | |

| Telephone: | |

| Inquiry: |

Warm hint:Please fill in the correct phone number to ensure that our sales personnel communicate with you.

Copyright © 2014-2021 BAOLAN EP INC.

Telephone: +86-135-8959-1050 +86-182-5337-2878 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province