- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact us

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

+86-182-5337-2878

Fax: +86-0533-3585998

E-mail: [email protected]

Tel: +86-135-8959-1050

+86-182-5337-2878

Fax: +86-0533-3585998

E-mail: [email protected]

Cases

> Cases >

New material factory ionization trap

At present, the business of Baolan enterprise users mainly covers three major business areas:

Field 1: Electromagnetic De-white;

Field 2: Dedusting, desulfurization and denitrification;

Field 3: VOCS organic waste gas treatment.

TEL:+86-135-8959-1050

Product introduction

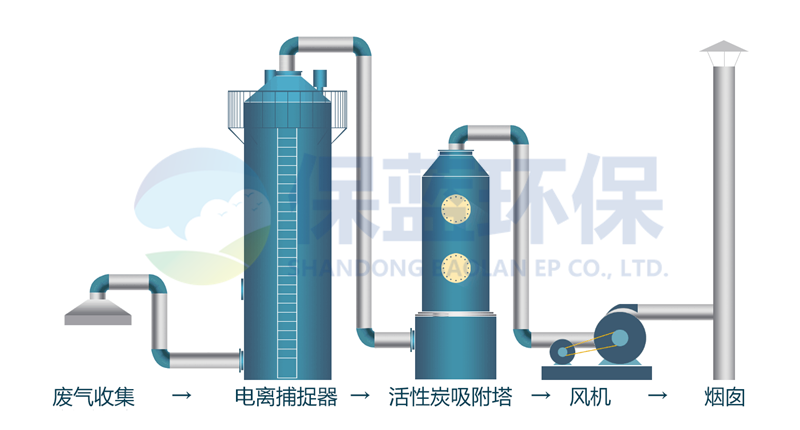

Considering the operating cost and safety of the waste gas treated in this project, the process route of this project adopts "ventilation system (fan, collection hood, pipe) + pretreatment system (ionization trap) + activated carbon adsorption" as the core process to treat the waste gas of this project. The process route diagram of the project is as follows:

Introduction to the process:

As a first step, after collecting the flue gas into the ionization trap, when the flue gas through the dust and tar material in the flue gas is in the charge under the action of ionization, to charge with wire and tube wall motion, and loss of charge, when the adsorption on precipitation in the miscellaneous quality increases to greater than its adhesion, under the action of gravity, automatically downflow, capture from ionization bottom discharge, net gas from ionization trap upper left and into the next procedure, hence leading to the degradation of pollutants removal.

The second step, after the collection of exhaust gas into the activated carbon adsorption equipment, the use of microporous active substances on the waste gas molecules or molecular group adsorption capacity. When the industrial waste gas passes through the adsorption medium, the molecules in it are "trapped" and adsorbed, so that the waste gas can be purified. The purified gas is discharged to the standard through the fan chimney.

As a first step, after collecting the flue gas into the ionization trap, when the flue gas through the dust and tar material in the flue gas is in the charge under the action of ionization, to charge with wire and tube wall motion, and loss of charge, when the adsorption on precipitation in the miscellaneous quality increases to greater than its adhesion, under the action of gravity, automatically downflow, capture from ionization bottom discharge, net gas from ionization trap upper left and into the next procedure, hence leading to the degradation of pollutants removal.

The second step, after the collection of exhaust gas into the activated carbon adsorption equipment, the use of microporous active substances on the waste gas molecules or molecular group adsorption capacity. When the industrial waste gas passes through the adsorption medium, the molecules in it are "trapped" and adsorbed, so that the waste gas can be purified. The purified gas is discharged to the standard through the fan chimney.

Case pictures

CONTACT

BAOLAN EP INC.

TEL:+86-135-8959-1050

FAX:+86-0533-3585998

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

FAX:+86-0533-3585998

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Procurement

| Your Name *: | |

| Email *: | |

| Telephone: | |

| Inquiry: |

Warm hint:Please fill in the correct phone number to ensure that our sales personnel communicate with you.

Copyright © 2014-2022 BAOLAN EP INC.

Telephone: +86-135-8959-1050 +86-182-5337-2878 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province