- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Tel: +86-135-8959-1050

+86-182-5337-2878

Fax: +86-0533-3585998

E-mail: [email protected]

In line with the principle of creating a good production and living environment for employees and surrounding residents, the leaders of the company plan to collect and process the gas produced by the company and completely eliminate the hidden trouble of the development of the enterprise. Entrusted by the company, shandong baolan environmental protection engineering co., ltd. for its preparation of boiler dust removal denitrification and desulfurization technology treatment preliminary design scheme. Based on the design principle of mature and reliable technology, reasonable overall layout, convenient operation and management, and low processing cost, we have compiled this scheme.

Flue gas mainly contains dust, sulfur dioxide, nitrogen oxides, and unburned hydrogen sulfide.Sulfur dioxide and hydrogen sulfide are harmful to life, and sulfur dioxide is 2.26 times heavier than air, which is colorless, smelly and suffocation gas. According to the data, after long-term exposure to SO2 with a concentration of 5.23±0.52mg/m3, the human body will suffer from bronchogenic pneumonia, hepatocellular turbiditis and eye keratitis lesions.Nitrogen oxides include a variety of compounds, such as nitrous oxide (N2O), nitric oxide (NO), nitrogen dioxide (NO2), nitrogen trioxide (N2O3), nitrogen tetroxide (N2O4) and nitrogen pentoxide (N2O5). Except for nitrogen dioxide, other nitrogen oxides are extremely unstable, when light, moisture or heat into nitrogen dioxide and nitric oxide, nitric oxide into nitrogen dioxide. Thus, exposure in the occupational environment is to a mixture of gases commonly called nitrous oxide (gas), mainly nitric oxide and nitrogen dioxide, and mainly nitrogen dioxide. Nitrogen oxides have different degrees of toxicity.

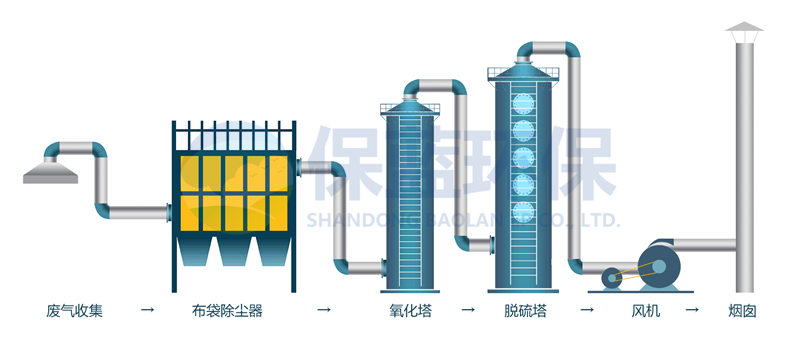

Considering the operation cost and safety of the treated waste gas, the process route of this plan is to adopt the "bag filter + oxidation tower + desulfurization tower + fan + chimney" as the core process to treat the waste gas. The schematic diagram of the process is as follows:

First step, the flue gas pipelines into the bag precipitator, bag filter in the gas purification way is outside the filter type, filter dust gas from the nozzle to the respective room, due to the design of the vertical distance from air inlet filter bag hooks, reasonable enough airflow through appropriate diversion and natural flow distribution, to achieve uniform indoor air distribution in the filter, dust particles of dust in the gas by natural sedimentation separation after directly into the hopper, the remaining dust under the guidance of the diversion system, with the air filter in the housing area, the adsorption on external surface of the filter bag.

The second step is sodium hypochlorite denitrification technology. Sodium hypochlorite is sprayed in the oxidation tower, and the strong oxidization of sodium hypochlorite is utilized to oxidize the low-value nitrogen oxides into high-value NOx that can be absorbed by the liquid. NOx continues to fuse with NaOH in the subsequent desulfurization tower to produce N2 and H2O.

Third step, after the dust of flue gas entering the desulfurization tower, double alkaline or flue gas desulfurization technology is the use of sodium hydroxide or sodium carbonate solution as the desulfurizer, sodium hydroxide or sodium carbonate solution directly into the washing removal of SO2 in flue gas desulfurization tower to achieve the goal of flue gas desulfurization, and desulfurization by regeneration into sodium sulfite and sodium hydroxide desulfurizer regeneration pool recycled back to the desulfurization tower again. After reaching the standard, the flue gas is discharged through the chimney of the fan pipeline.

FAX:+86-0533-3585998

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

| Your Name *: | |

| Email *: | |

| Telephone: | |

| Inquiry: |

Copyright © 2014-2021 BAOLAN EP INC.

Telephone: +86-135-8959-1050 +86-182-5337-2878 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province