- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact us

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

+86-182-5337-2878

Fax: +86-0533-3585998

E-mail: [email protected]

Tel: +86-135-8959-1050

+86-182-5337-2878

Fax: +86-0533-3585998

E-mail: [email protected]

Cases

> Cases >

Electric tar precipitator

At present, the business of Baolan enterprise users mainly covers three major business areas:

Field 1: Electromagnetic De-white;

Field 2: Dedusting, desulfurization and denitrification;

Field 3: VOCS organic waste gas treatment.

TEL:+86-135-8959-1050

Product introduction

The company attaches great importance to environmental protection while vigorously improving the economic benefits of the enterprise and paying attention to product quality. The company leaders, in line with the principle of creating a good production and living environment for the employees and the surrounding residents, collect and deal with the waste gas generated in the operation process and completely eliminate the hidden dangers of the enterprise's development. Entrusted by the company, shandong baolan environmental protection engineering co., LTD. Based on the design principle of mature and reliable technology, reasonable overall layout, convenient operation and management, and low processing cost, we have compiled this scheme.

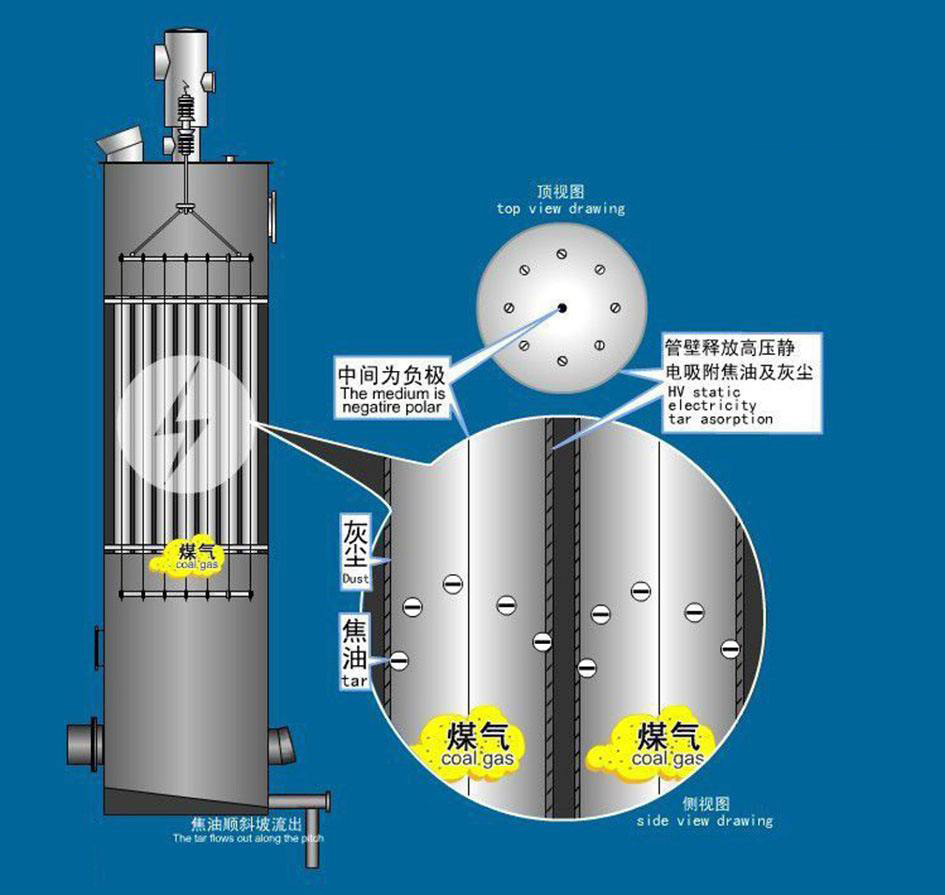

It works by applying a high-voltage direct current between the metal wire and the metal tube wall (or plate) to maintain an electric field strong enough to ionize the gas, creating a corona zone between the anode and cathode.

According to the electric field theory, the positive ions are adsorbed on the negative corona electrode, and the negative ions are adsorbed on the positive precipitation electrode. All ionized positive and negative ions fill the entire space between the corona pole and the precipitation pole.

When the gas containing impurities such as tar droplets passes through the electric field, the impurities adsorbed with negative ions and electrons move to the precipitation pole under the action of the electric field's coulomb force, releasing the charge and adsorbed on the precipitation pole, thus achieving the purpose of purifying the gas, which is usually called the phenomenon of charge. When the impurity mass adsorbed on the precipitator increases to more than its adhesion force, it will automatically flow down and discharge from the bottom of the ionization trap, while the net gas will leave from the top of the ionization trap and enter the next process.

Ionization trap working principle diagram

CONTACT

BAOLAN EP INC.

TEL:+86-135-8959-1050

FAX:+86-0533-3585998

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

FAX:+86-0533-3585998

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Procurement

| Your Name *: | |

| Email *: | |

| Telephone: | |

| Inquiry: |

Warm hint:Please fill in the correct phone number to ensure that our sales personnel communicate with you.

Copyright © 2014-2021 BAOLAN EP INC.

Telephone: +86-135-8959-1050 +86-182-5337-2878 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province