The company attaches great importance to the environmental protection work as well as the product quality while vigorously improving the economic benefits of the enterprise. Based on the principle of creating a good production and living environment for the employees and surrounding residents of the enterprise, the leaders of the company collect and treat the waste gas generated in the operation process, so as to thoroughly eliminate the development potential of the enterprise. Entrusted by the company, Shandong Baolan Environmental Protection Engineering Co., Ltd. prepared the preliminary design scheme for waste gas treatment. Based on the design principles of mature and reliable technology, reasonable overall layout, convenient operation and management, and low treatment cost, we have prepared this plan.

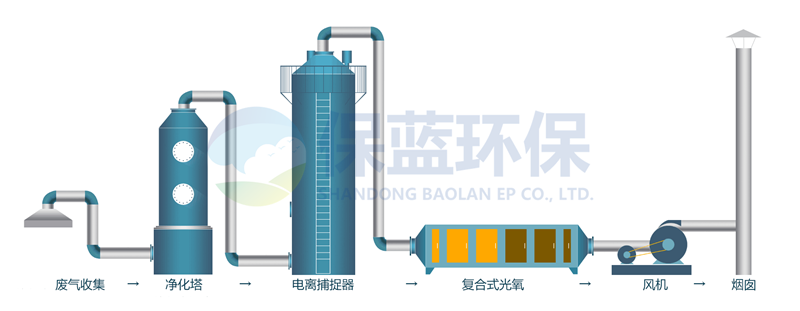

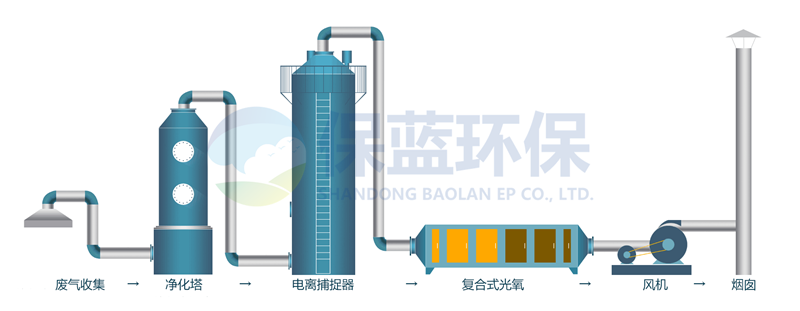

According to the operation cost and safety of the waste gas treated in the project, the process of the project is planned to adopt the core process of "purification tower + ionization catcher + composite photooxygen" to treat the waste gas. The process flow chart of the project is as follows:

Process introduction:

In the first step, the collected waste gas first enters the purification tower, and the gas enters the tower from the air inlet at the lower part of the tower and moves upward, and the liquid drop ejected from the nozzle moves downward. At the same time, the tower is equipped with packing to increase the contact area of gas and liquid, make the gas fully contact with the liquid drop, enhance the mass transfer efficiency, and achieve the purpose of cooling and catching dust.

In the second step, the collected waste gas enters into the ionization trapper. When the waste gas passes through, the dust and tar substances in the waste gas are ionized under the action of electric charge, moving to the charged metal wire and tube wall, and losing the charge. When the impurity mass adsorbed on the precipitation pole is added to be greater than its adhesion, under the action of gravity, it will flow down automatically, from the ionization trapper The bottom of the device is discharged, and the net gas leaves from the upper part of the ionization trapper and enters the next process, so that the pollutants can be degraded and removed.

In the third step, the captured exhaust gas enters into the compound photo oxygen device. In this device, the ozone and · Oh (hydroxyl radical) produced by the reaction of high-energy photon beam and air react to decompose and oxidize the odorous gas. At the same time, the chain structure of macromolecular odorous gas is broken under the action of high-energy photon, which makes most of the organic gas substances transform into odorless micromolecule Or completely mineralized, producing water and CO2. The waste gas enters the zeolite molecular sieve layer for deep purification, and finally it is discharged through the fan pipe chimney to meet the standard.