Welcome to BAOLAN EP INC.

24-Hour Hotline

- Carbon Capture Utilization

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Cases

> Cases >

Chemical waste gas treatment

At present, the business of Baolan enterprise users mainly covers three major business areas:

Field 1: Electromagnetic De-white;

Field 2: Dedusting, desulfurization and denitrification;

Field 3: VOCS organic waste gas treatment.

TEL:+86-135-8959-1050

Product introduction

The company attaches great importance to environmental protection while vigorously improving the economic benefits of the enterprise and paying attention to product quality. The company leaders, in line with the principle of creating a good production and living environment for the employees and the surrounding residents, collect and deal with the gas generated in the production process and completely eliminate the hidden dangers of the enterprise's development. Entrusted by your company, shandong baolan environmental protection engineering co., LTD has prepared a preliminary design scheme for waste gas treatment. Based on the design principle of mature and reliable technology, reasonable overall layout, convenient operation and management, and low processing cost, we have compiled this scheme.

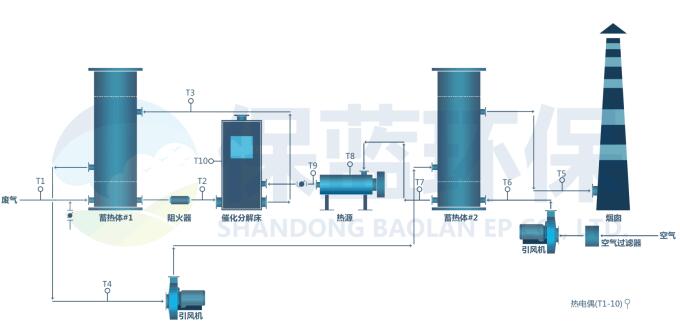

Considering the operating cost and safety of the waste gas treated in this project, the process route of this project adopts the "safe catalytic combustion" as the core process to treat the waste gas of this project. The process route diagram of the project is shown as follows:

★This diagram is exclusive to our company: it solves the security problem

1. The exhaust gas passes through the heat accumulator #1, raising the temperature from 10℃ to 150℃. The heat source is the high-temperature gas (300-350℃) after the reaction of the catalytic decomposition device. Temperature recovery and utilization, reduce system operation cost;

2. after preheating gas into the catalytic decomposition after flame arrester device, the device at the bottom of the mixing chamber in the mixed with high temperature (480 ℃) on air, make the exhaust gas temperature to 300 ℃ or so, reach the catalytic reaction temperature, and then air currents to rise to the catalytic reaction zone, on the surface of the catalyst, decomposed into CO2 and H2O, finally in the outlet at the bottom of the body;

3. under the action of induced draft fan, high temperature gas through the regenerator # 1, by indirect heat exchange the initial exhaust gas to heat up, and then out of the regenerator # 1, through the induced draft fan to the regenerator # 2, as the heat source will need to be heated air preheated again, make the air heat from room temperature to 100 ℃, the temperature recycling, reduce the system operation cost, and then into the chimney standards;

4. The preheated air enters the air heater. Under the action of electric heating rod, the air is heated from 100℃ to 480℃.

2. after preheating gas into the catalytic decomposition after flame arrester device, the device at the bottom of the mixing chamber in the mixed with high temperature (480 ℃) on air, make the exhaust gas temperature to 300 ℃ or so, reach the catalytic reaction temperature, and then air currents to rise to the catalytic reaction zone, on the surface of the catalyst, decomposed into CO2 and H2O, finally in the outlet at the bottom of the body;

3. under the action of induced draft fan, high temperature gas through the regenerator # 1, by indirect heat exchange the initial exhaust gas to heat up, and then out of the regenerator # 1, through the induced draft fan to the regenerator # 2, as the heat source will need to be heated air preheated again, make the air heat from room temperature to 100 ℃, the temperature recycling, reduce the system operation cost, and then into the chimney standards;

4. The preheated air enters the air heater. Under the action of electric heating rod, the air is heated from 100℃ to 480℃.

CONTACT

BAOLAN EP INC.

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province