Welcome to BAOLAN EP INC.

24-Hour Hotline

- Carbon Capture Utilization

- VOCs series

- DeSOx-DeNOx-Dedust

- Consumables

Contact Baolan

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province

Tel: +86-135-8959-1050

E-mail: [email protected]

Tel: +86-135-8959-1050

E-mail: [email protected]

Industry Knowledge

The process principle of COA denitrification

时间: 2025-07-09 15:35

COA denitrification (Catalytic Oxidation-Ammonia) process is a catalytic oxidation ammonia method for denitrification technology, mainly used for the removal of nitrogen oxides (NOx) in industrial flue gas.

It is a transitional process betw

COA denitrification (Catalytic Oxidation-Ammonia) process is a catalytic oxidation ammonia method for denitrification technology, mainly used for the removal of nitrogen oxides (NOx) in industrial flue gas.

It is a transitional process between Selective Non-Catalytic Reduction (SNCR) and Selective Catalytic Reduction (SCR).

This process is commonly used in medium and low temperature denitrification scenarios, especially suitable for conditions where high temperature or traditional SCR conditions are inconvenient.

It is a transitional process between Selective Non-Catalytic Reduction (SNCR) and Selective Catalytic Reduction (SCR).

This process is commonly used in medium and low temperature denitrification scenarios, especially suitable for conditions where high temperature or traditional SCR conditions are inconvenient.

1. Principle of COA denitrification process:

The core of COA denitrification is to oxidize NO (nitrogen oxide) into NO2 or other active components under the action of a catalyst, then react with the reductant (such as ammonia NH3), and finally reduce to harmless nitrogen (N2) and water (H2O).

2. Reaction steps are as follows:

Oxidation reaction (catalyst front section):

2NO + O2→2NO2

Reduction reaction (catalyst rear section):

2NO2+4NH3→3N2+6H2O

Or:

NOx+NH3→N2+H2O

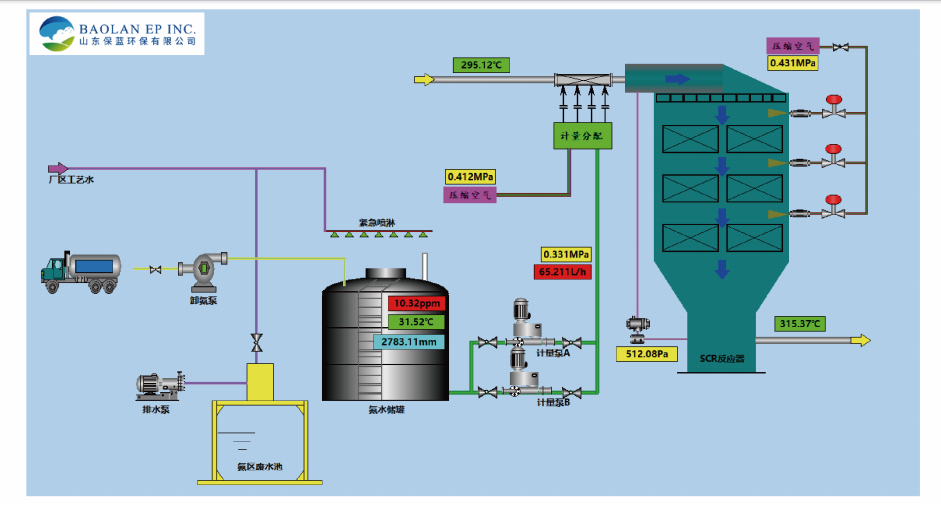

3. Composition of COA denitrification system:

Pretreatment system (dust removal, cooling)

Oxidation catalytic section (efficient oxidation of NO to NO2)

Ammonia injection mixing system (precise NH3 dosing)

Reduction catalytic section (reaction and reduction of NO2 with NH3)

Automatic control system (adjust ammonia-nitrogen ratio, temperature, flow rate, etc.)

4. Applicable scope:

Glass, ceramics, building materials, chemical industry, and other industries;

Flue gas temperature: 180~300℃;

Initial NOx concentration: 100~800 mg/m³;

Emission standard requirements: <50 mg/m³ or lower.

5. Advantages:

Low reaction temperature, energy saving;

Low ammonia slip rate, environmentally safe;

Compact process flow, suitable for old plant renovation;

Long catalyst life, low operating cost.

If you have any ideas, we look forward to hear about your suggestions!

If you have any ideas, we look forward to hear about your suggestions!

Copyright © 2014-2023 BAOLAN EP INC.

Telephone: +86-135-8959-1050 E-mail: [email protected]

Address: Jurong East Road, Huantai Industrial Park, Zibo City, Shandong Province