Regenerative Catalytic Oxidizer (RCO)

Technology Introduction

① Resolved safety issues. Only 200-400 ℃ can be used to catalyze the decomposition of almost all organic matters, avoiding the potential fire safety hazards faced by conventional TO, RTO, RCO incineration.

② The problem of purification efficiency is solved. Its efficiency is over 99%, and other purification methods (condensation recovery, TO incineration, adsorption, plasma, photolysis, etc.) are low, and the problem of unqualified emissions.

③ The problem of input cost was solved.

④ Solved the problem of running costs. Compared with the adsorption method, RCO has extremely low operating costs. It can almost maintain self-normal operation under conditions where the concentration is greater than 1000 ppm, without the need to consume other energy.

⑤ Solved the problem of personnel maintenance. The entire set of equipment adopts PLC automatic control system, which is automatically adjusted according to the trend of concentration and temperature changes.

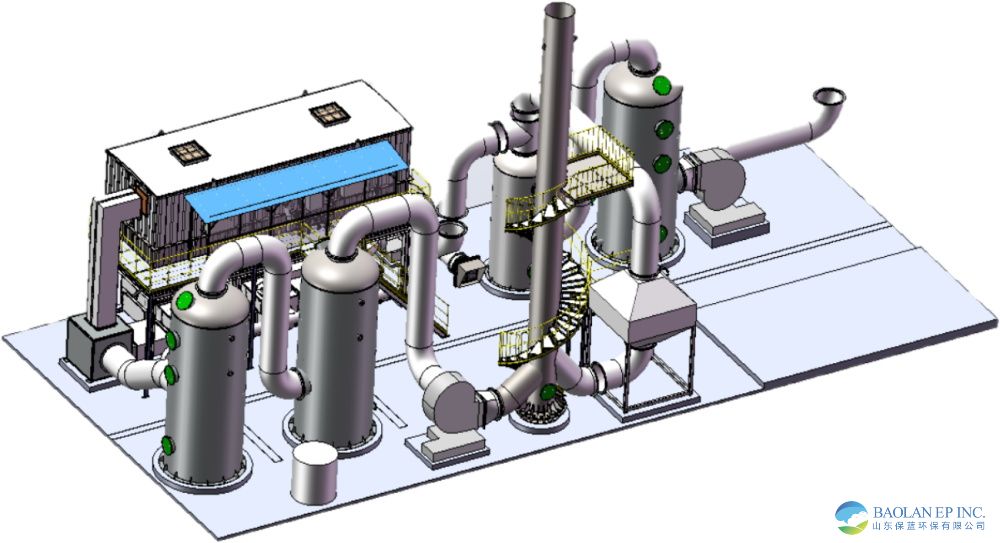

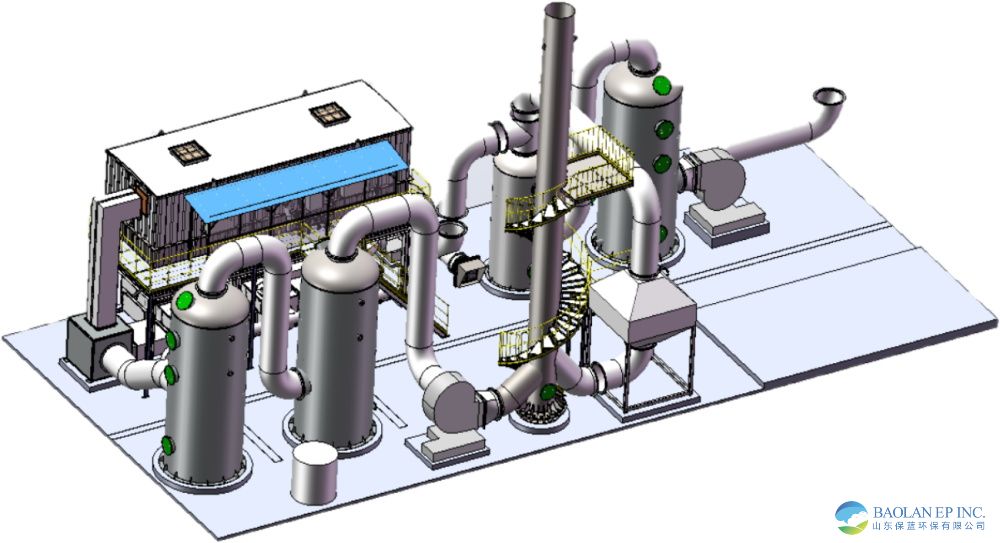

System structure

The RCO catalytic decomposition device consists of a pretreatment device, a preheating device, a catalytic combustion device, and an explosion-proof device.

① Exhaust gas pretreatment: In order to avoid catalyst bed blockage and catalyst poisoning, the exhaust gas must be pretreated before entering the bed to remove dust, droplets and catalyst poisons in the exhaust gas.

② Preheating device: Preheating device includes exhaust gas preheating device and catalyst burner preheating device. Because the catalyst has a catalytic activity temperature, it is called the catalyst light-off temperature for catalytic combustion. The temperature of the exhaust gas and the bed must reach the light-off temperature for catalytic combustion. Therefore, a preheating device must be provided. However, in the case where the temperature of the exhaust gas itself is relatively high, such as enameled wire, insulation material, baking paint and other dry exhaust gas, the temperature can reach 300 ° C or more, it is not necessary to set a preheating device.

③ Catalytic combustion device: Generally, a fixed-bed catalytic reactor is used. The design of the reactor is carried out according to specifications, which should be easy to operate, easy to maintain, and convenient for loading and unloading catalyst.

④ Explosion-proof device: Explosion-proof for diaphragm pressure relief, installed on the top of the host. When an accident occurs during the operation of the equipment, the pressure can be cracked in time to prevent the accident.

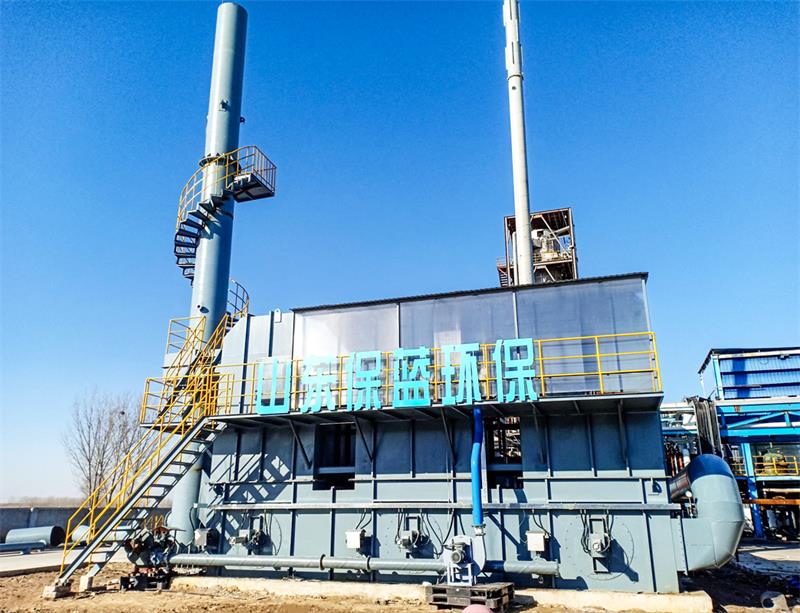

Technical advantages

1. Low operating cost. Generally, when the organic waste gas reaches a certain concentration (above 1000mg / m3), the heating chamber in the purification device does not need auxiliary heating, which saves costs;

2. Does not produce secondary pollutants such as nitrogen oxides (NOX);

3. Fully automatic control and convenient operation management;

4. Because it is flameless combustion, it has good safety and purification efficiency of more than 99%, which is especially suitable for processing continuously discharged gases;

5. Reuse the heat generated by the combustion of exhaust gas to save energy consumption; efficient heat recovery rate, heat recovery efficiency ≥95%.

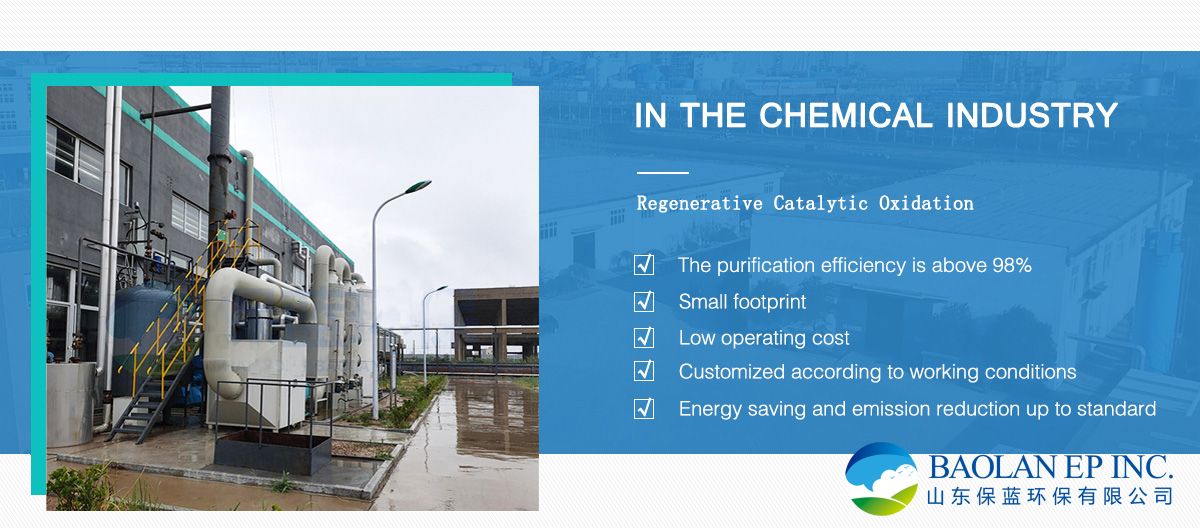

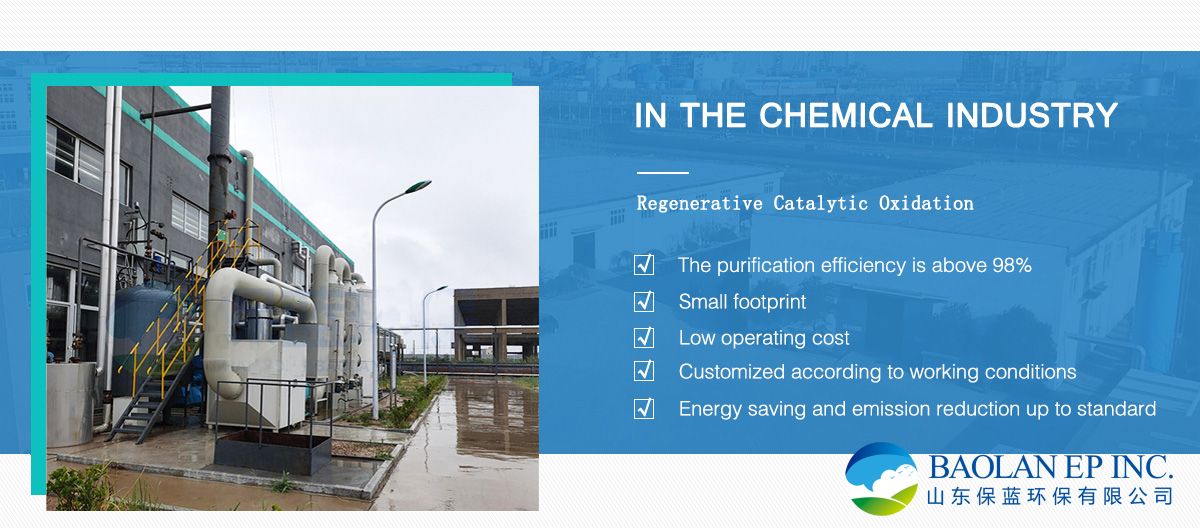

Application Areas

RCO equipment can be directly applied to the purification of organic waste gas with medium and high concentration (100mg / m3-10000 mg / m3);

RCO equipment can also be applied to activated carbon adsorption and concentration catalytic combustion system, which is used to replace catalytic combustion and heater parts;

RCO treatment technology is especially suitable for the occasions with high demand for heat recovery rate, and also for the same production line. Due to the different products, the components of the exhaust gas often change or the concentration of the exhaust gas fluctuates greatly.