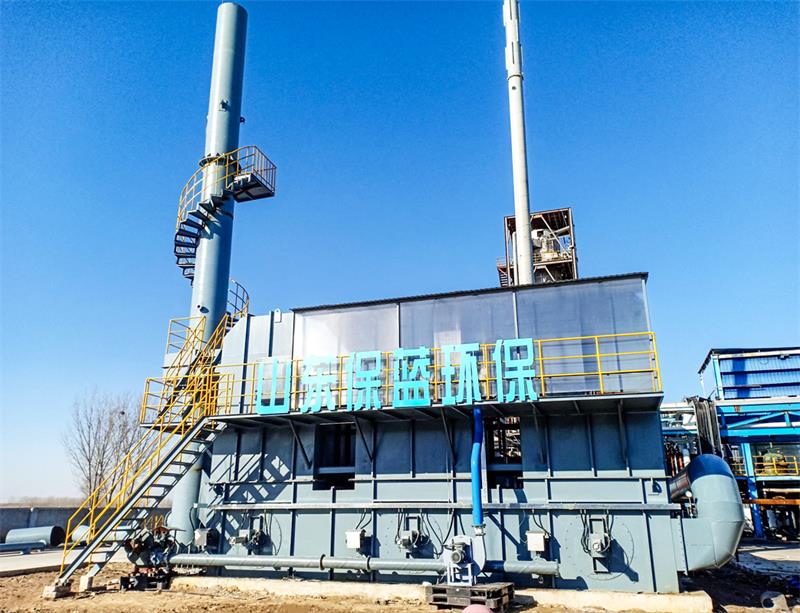

- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

- Product Details

Thermal Oxidizer (TO)

Technology Introduction

TO, fully known as Thermal Oxidizer or Thermal Incineration, is a very effective and widely applied end-of-pipe treatment technology.

Working Principle

The core principle of TO technology is very simple and straightforward: at high temperatures, volatile organic compounds (VOCs) in organic waste gas react with oxygen through oxidation, completely decomposing into harmless carbon dioxide (CO₂) and water (H₂O), releasing heat.

The general chemical reaction can be expressed as:

Organic compounds (VOCs) + Oxygen (O₂) + Heat → Carbon dioxide (CO₂) + Water (H₂O) + Heat

The essence of this process is a vigorous combustion (oxidation) reaction, similar to the combustion we encounter in daily life, but it is controlled and carried out inside specially designed incinerators.

The Three Key Elements

To achieve efficient and thorough decomposition of VOCs (usually requiring destruction removal efficiency of 98% or even above 99%), three key conditions must be met simultaneously, known as the "3T" principle:

1. Temperature: Provide a sufficiently high reaction temperature environment to ensure molecules gain enough energy to break chemical bonds. The required temperature varies for different types of VOCs, generally between 750°C and 950°C. For difficult-to-degrade substances containing halogens, higher temperatures may be needed.

2. Time: Ensure the waste gas stays in the high-temperature zone long enough for the oxidation reaction to fully proceed. This time is usually between 0.5 and 2.0 seconds.

3. Turbulence: Also called mixing degree. The waste gas must be fully and evenly mixed with oxygen (air) to avoid dead zones and short circuits, ensuring all VOC molecules contact oxygen and react.

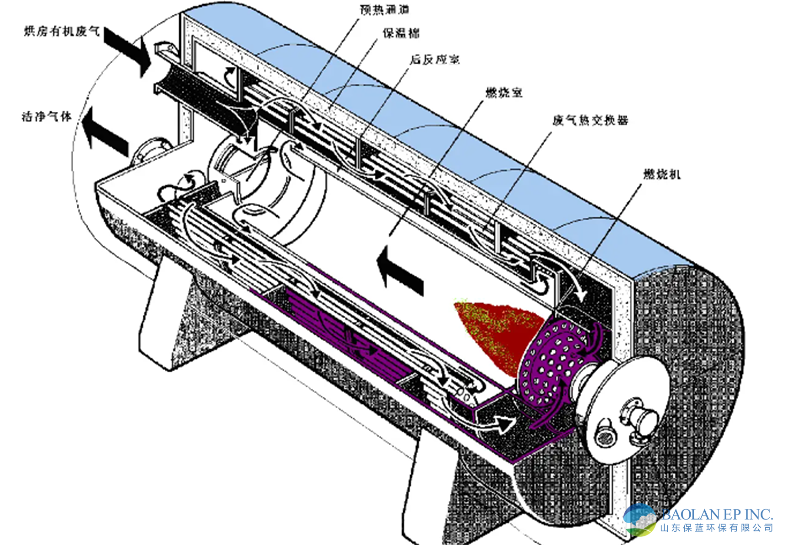

Basic Process Flow

A typical TO system usually includes the following main parts:

1. Waste Gas Pretreatment: Before entering the incinerator, the waste gas may need pretreatment such as filtration (to remove dust and particulates) and dehumidification to protect downstream equipment.

2. Incinerator (Combustion Chamber): This is the core of the TO system. The furnace body is built with refractory materials capable of withstanding high temperatures. It is equipped with burners to heat the furnace chamber to the set reaction temperature during startup. When the waste gas concentration is sufficiently high, the burner can reduce firepower or shut off to achieve self-sustaining heat operation.

3. Heat Recovery System: This is key to the economic efficiency of the TO system. Direct discharge of high-temperature flue gas (usually above 500°C) causes huge energy waste. Therefore, most TO systems are equipped with heat recovery devices:

Recuperative Heat Exchanger (heat recovery rate 50%-85%): The most common form. High-temperature flue gas heats the incoming cold waste gas through the exchanger tube walls, preheating the cold waste gas to a higher temperature (usually 300-600°C), greatly reducing auxiliary fuel consumption.

Regenerative Heat Exchanger (heat recovery rate 90%-95%): Used in regenerative thermal oxidizers (RTO), with higher recovery efficiency, currently the mainstream and efficient configuration.

4. Post-Treatment System: If the waste gas contains halogen elements such as chlorine, sulfur, or fluorine, acidic gases (such as HCl, SOx, etc.) will be produced after combustion. Alkali scrubbers and other post-treatment facilities are required to neutralize and remove these acidic substances before compliant discharge.

Technical advantages

High Efficiency and Stability: Extremely high processing efficiency, capable of handling various complex and high-concentration VOCs waste gases.

Wide Applicability: Can process almost all types of organic waste gases, unaffected by changes in composition.

Complete Decomposition: Directly converts organic substances into CO₂ and H₂O, with no secondary pollution (provided that post-treatment is adequate).

High Reliability: Mature technology with stable operation.