- Product Details

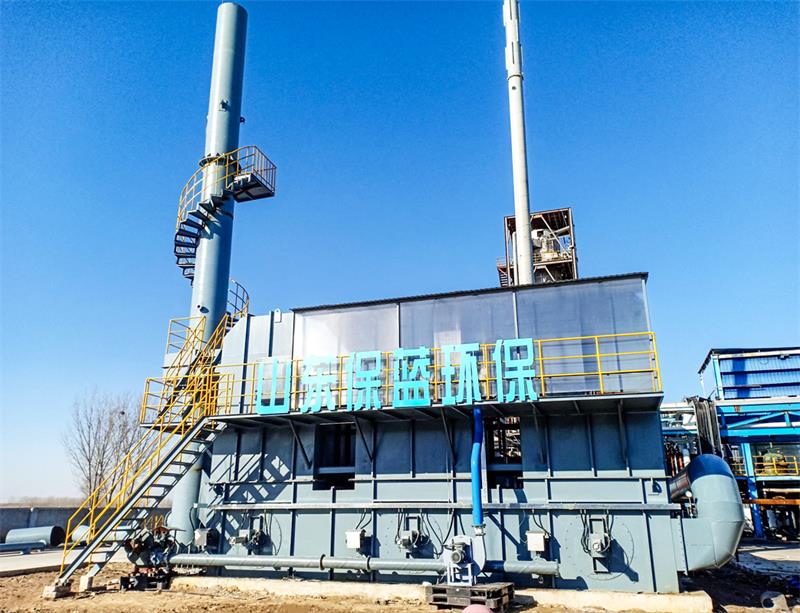

Rotary Regenerative Thermal Oxidizer (RTO)

Technology Introduction

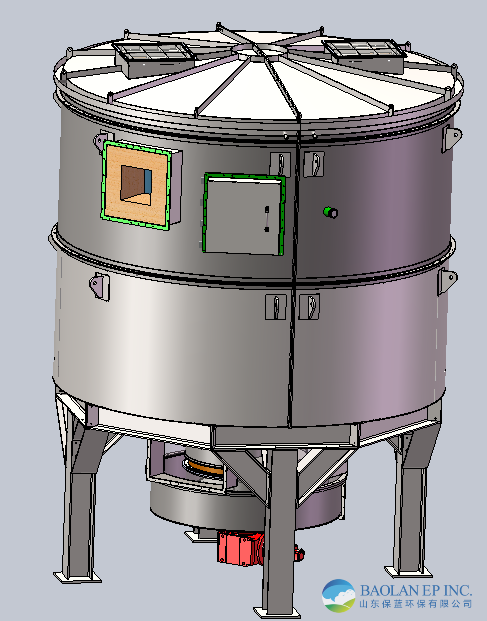

The rotary RTO mainly consists of a combustion chamber, a ceramic packing bed and a rotary valve, etc. The furnace body is divided into 12 chambers, with 5 chambers for exhaust gas intake, 5 chambers for purified gas output, 1 chamber for cleaning, and 1 chamber for isolation. The exhaust gas distribution valve is driven by a motor to rotate continuously and at a constant speed. Under the action of the rotary valve, the exhaust gas slowly switches continuously among the 12 chambers.

Working Principle

The Rotary Rto works on the principle of heating organic waste gas to over 760℃ and holding it for more than one second, so that the VOCs in the waste gas are oxidized and decomposed into carbon dioxide and water. The high-temperature gas produced by oxidation flows through specially designed ceramic heat storage bodies, heating the ceramic bodies to "store heat". This "stored heat" is used to preheat the subsequent organic waste gas entering the furnace, thereby saving fuel consumption for heating the waste gas and reducing operating costs.

Detailed Technical Principle

The rotating RTO uses 12 fixed regenerative chambers (numbered 1-12#) equipped with honeycomb ceramics. The exhaust gas is preheated in five regenerative chambers (such as No. 1-5 regenerative chambers as the intake area) and then enters the oxidation chamber. The combustion of gas in the oxidation chamber raises the indoor temperature to the oxidation temperature. The high-temperature gas after oxidation of the exhaust gas is cooled and discharged through another five regenerative chambers (7-11# regenerative chambers are exhaust zones). The other two, 6# regenerative chambers are purging zones, and 12# regenerative chambers are idle. The rotation of the RTO is controlled by the rotary valve to continuously switch the exhaust gas in the heat storage chamber and operate in a sequential progressive cycle. The rotary RTO adopts a brand-new gas isolation sealing technology. The sealing strip has a certain wind wear compensation effect and is also convenient for maintenance and replacement. The airflow fluctuations at the inlet and outlet are small, which does not affect the front-end process production line. The rotary RTO realizes the relative independence of the furnace body and valves, which is also convenient for installation and maintenance, operates more smoothly, and enables the decomposition rate of organic waste gas to reach over 99%.

The oxidation chamber has two functions: one is to ensure that the combustion of waste gas can reach the designed oxidation temperature, and the other is to ensure that there is sufficient residence time for the VOCs in the waste gas to be fully oxidized.

Technical advantages

High processing efficiency (over 99%) and thermal energy recovery rate (over 95%)

The equipment has little load variation, a long service life and is stable

It occupies a small area.

The driving part and heat storage body are made of semi-permanent materials, with low maintenance costs.

The temperature of the stored heat energy can be maintained for a long time, and fuel costs can be saved when restarting.

The possibility of secondary pollution is small and the environmental protection performance is high