- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

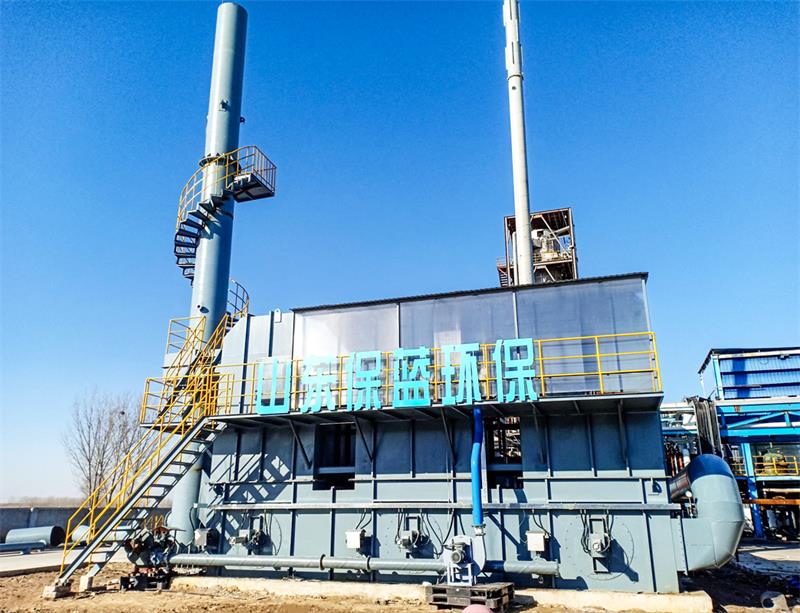

- Product Details

Magnetic Energy De-white

Technology Introduction

Whitening is the abbreviation for removing white smoke, which refers to the removal of white mixed pollutants from industrial emissions.

Magnetic energy whitening refers to the use of electromagnetic energy to remove white smoke devices, effectively removing and purifying mixed pollutants in white smoke, thereby achieving ultra clean emissions of smoke. The white mixed pollutants include harmful substances such as dust particles, acid mist, alkali mist, aerosols, soluble salts, PM10, PM2.5, CPM, etc. (white smoke, black smoke, blue smoke, yellow smoke), and the "online detection" value of these harmful substances is close to zero emissions! Balancing the elimination of visual pollution!

Magnetic Energy White Smoke Elimination: Precisely Solving White Smoke Pollution

Faced with the concealment and hazards of white smoke plume pollution, magnetic energy white elimination technology has emerged as an effective solution to address current and future environmental challenges over the next 10-30 years. Through the triple synergistic effects of tempering,pulsing and induction, magnetic energy white elimination efficiently removes white mixed pollutants after wet desulfurization; the purified online detection values approach zero emissions, simultaneously eliminating visual pollution and odors; the equipment operates without consumables, avoiding secondary pollution that may occur in traditional treatment processes, truly achieving ultra-clean emissions.

The white smoke plume produced after wet flue gas desulfurization was once a "blind spot" in environmental awareness. With deeper understanding of pollutants such as CPM, its potential hazards have gradually become apparent. Magnetic energy white smoke elimination technology not only reveals the pollution truth behind the "white smoke" but also provides an effective solution. Under the dual-carbon background, enterprises proactively adopting innovative environmental protection technologies not only comply with policy requirements but also contribute to their own sustainable development. Completely eliminating the "white smoke" not only demonstrates corporate responsibility but also promotes the entire industry toward a green future.

Technical Advantages

① High purification efficiency

The magnetic energy de-whitening equipment integrates three magnetic energy purification technologies: quenching and tempering, pulse, and induction, with an overall processing efficiency of over 97%. When the flue gas enters the equipment, the magnetic energy quickly acts on the white flue gas mixed pollutants, including dust particles, acid mists, alkali mists, aerosols, soluble salts, PM10, PM2.5, CPM, etc., magnetizing them to form "magnetic agglomeration". These aggregates adhere to the inner wall of the magnetic energy tube to form a liquid film, and are eventually discharged in an orderly manner through the drain outlet, achieving deep purification of flue gas. The online monitoring values of the purified flue gas approach zero, while effectively eliminating visual pollution and odors

② Less secondary pollution

From the very beginning of the research and development, the focus was on the process reengineering of traditional flue gas treatment equipment,aiming to solve problems such as complex equipment structure, high consumable costs, and chemical agent blockages. The no-consumables design of magnetic energy de-whitening reduces the risk of secondary pollution from the source, which is in line with the national green development concept. Meanwhile, magnetic energy de-whitening technology also focuses on the sustainable utilization of energy. While rationally treating harmful substances and impurities in flue gas, it recovers and utilizes thermal energy and water resources.

From the very beginning of the research and development, the focus was on the process reengineering of traditional flue gas treatment equipment, aiming to solve problems such as complex equipment structure, high consumable costs, and chemical agent blockages. The no-consumables design of magnetic energy de-whitening reduces the risk of secondary pollution from the source, which is in line with the national green development concept. Meanwhile, magnetic energy de-whitening technology also focuses on the sustainable utilization of energy. While rationally treating harmful substances and impurities in flue gas, it recovers and utilizes thermal energy and water resources.

③ Low operating energy consumption

Magnetic energy de-whitening technology enables efficient energy utilization. Electromagnetic energy directly acts on pollutants and water mists in flue gas, avoiding the significant energy loss in the form of thermal and chemical energy in traditional technologies. By integrating AI intelligent technology, the equipment can adjust its operating power in real time according to the dynamic changes in flue gas volume, eliminating the need for continuous full-load operation. This ensures the purification effect while significantly reducing ineffective energy consumption.

④ High safety level

The magnetic energy de-whitening equipment has excellent safety performance. The internal design structure of the system is simple, with few rotating devices and fewer failure points and maintenance points. The external design fully takes environmental factors into account and is equipped with eight levels of safety prevention and control measures, including lightning protection, electric shock protection, fire prevention, explosion prevention, poison prevention, leakage prevention, high-temperature prevention and corrosion prevention, to comprehensively ensure production safety. The core components of the equipment are made of structurally stable graphene material, effectively avoiding the risks of corrosion and leakage. The intelligent system conducts real-time monitoring to ensure the safe operation of the equipment.

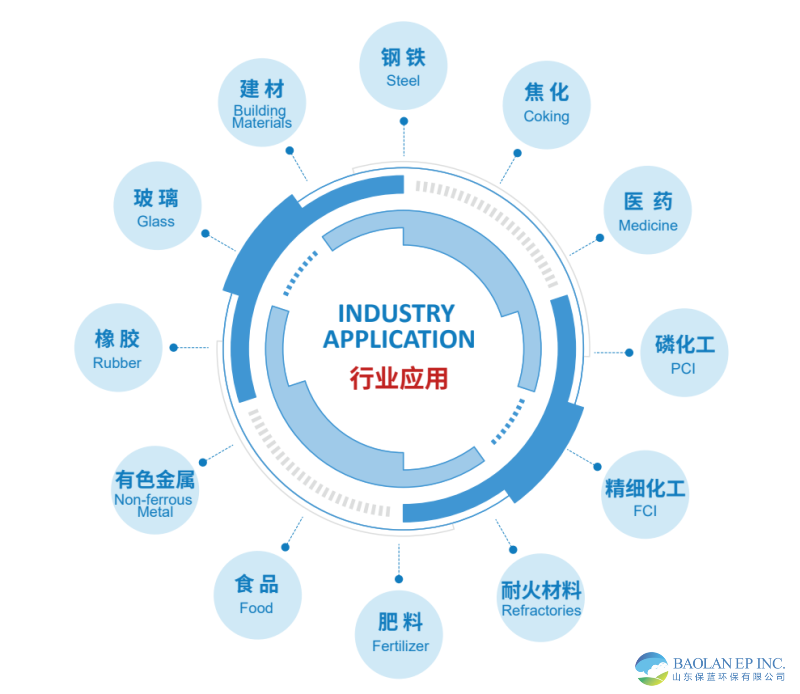

Aplication Areas