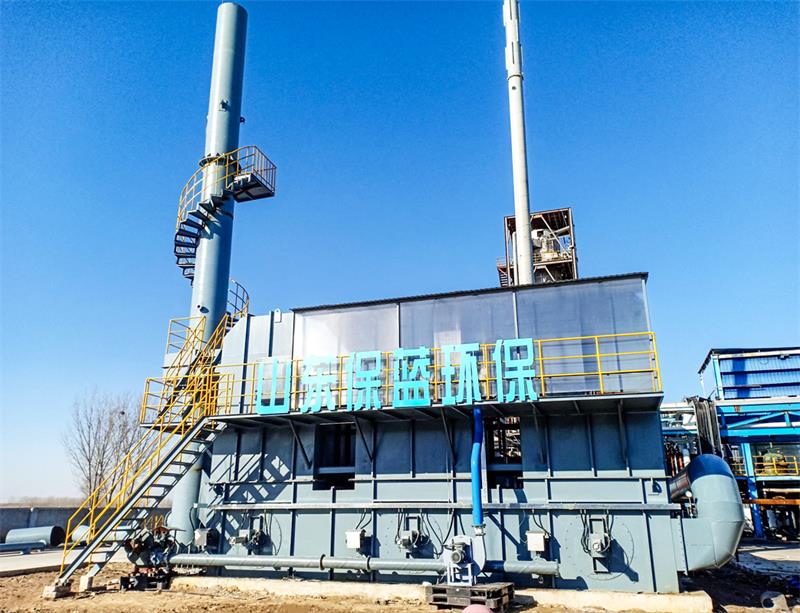

- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

- Product Details

Catalytic Oxidizer (CO)

Technology Introduction

Catalytic Oxidation is an efficient and mature VOCs treatment technology, especially suitable for treating low to medium concentration (usually referring to several hundred to several thousand mg/m³) organic waste gases.

Working Principle

The core principle of catalytic combustion technology is: under the action of a catalyst, the VOCs components in the organic waste gas undergo flameless combustion with oxygen at a relatively low temperature (usually 250°C - 400°C), being deeply oxidized and decomposed into harmless carbon dioxide (CO₂) and water (H₂O), releasing heat.

Detailed Technical Principle

1. Catalysis

This is the soul of the technology. The catalyst itself does not participate in the reaction but can greatly reduce the activation energy of the reaction.

Compared to direct combustion (TO): direct combustion (thermal combustion) requires very high temperatures (usually 700°C - 850°C or even higher) to ensure complete destruction of VOCs, resulting in extremely high energy consumption.

Catalytic combustion (CO): with the catalyst, the oxidation reaction can be rapidly completed at much lower temperatures (e.g., 300°C - 350°C). This brings two major benefits:

Significantly reduces fuel consumption: the energy required to preheat the waste gas to the reaction temperature is greatly reduced, lowering operating costs.

Avoids secondary pollution: low-temperature combustion effectively suppresses the formation of thermal nitrogen oxides (NOx), whereas high-temperature direct combustion easily produces NOx as a new pollutant.

2. Process Stages

A typical catalytic combustion system usually includes the following key steps:

a. Pretreatment

Before entering the catalytic bed, the waste gas must be pretreated to remove dust, particulates, paint mist, heavy metals, and other impurities. These substances can cover the active surface of the catalyst, clog its pores, cause catalyst poisoning or deactivation, seriously affecting treatment efficiency and service life.

b. Preheating

The filtered waste gas is sent by a fan into a heat exchanger to exchange heat with the high-temperature purified gas after the reaction (this step is for energy recovery and energy saving). Then, the waste gas enters the preheating chamber (usually assisted by an electric heater or gas burner) and is heated to the ignition temperature required for the catalytic reaction.

c. Catalytic Reactio

The waste gas that reaches the ignition temperature passes evenly through the catalytic bed. The catalytic bed is filled with a special catalyst (usually a honeycomb carrier coated with precious metals or metal oxide active components). VOC molecules fully contact oxygen here and undergo catalytic oxidation on the catalyst surface, rapidly generating CO₂ and H₂O.

d. Heat Recovery and Emission

The high-temperature clean gas generated after the reaction enters the heat exchanger to exchange heat with the incoming low-temperature waste gas, preheating the gas to be treated, thereby greatly reducing system energy consumption. Finally, the cooled clean gas is discharged through the chimney in compliance with standards.

Core Components of the System

1. Catalyst: The core of the system.

Common types include:

Precious metal catalysts: such as platinum (Pt), palladium (Pd), rhodium (Rh), etc., which have high activity and low ignition temperature but are expensive.

Transition metal oxide catalysts: such as oxides of copper, chromium, manganese, cobalt, nickel, etc., which are lower in cost but may have slightly lower activity and stability compared to precious metals.

Support: usually honeycomb ceramics or metal honeycombs, providing a large specific surface area to ensure sufficient contact between exhaust gas and catalyst.

2. Catalytic bed/reactor: a container loaded with catalyst, designed to ensure uniform airflow distribution without short-circuit dead zones.

3. Heat exchanger: recovers reaction heat; the efficiency of preheating directly determines the system's energy consumption level. Common types include plate, tube, and regenerative heat exchangers.

4. Preheater: electric heater or gas burner used to heat the exhaust gas to the ignition temperature during system startup.

5. Fan: provides the driving force for exhaust gas flow.

Technical advantages

High purification efficiency: removal rates for most VOCs can reach over 95%, even 99%.

Low operating temperature: significant energy-saving effect and relatively low operating cost.

No secondary pollution: effectively suppresses NOx formation.

High safety: no open flame combustion, safe and reliable.

Wide adaptability: can treat various medium and low concentration organic compounds.