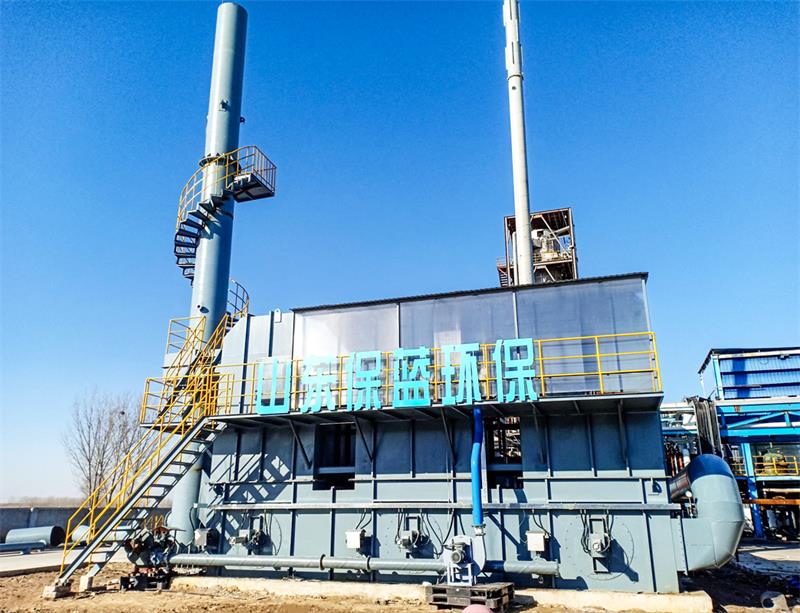

- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

- Product Details

Municipal Solid Waste Incinerator

Core Objectives

The main objectives of municipal solid waste incineration technology are threefold, commonly referred to as an extension of the "3R" principle or "harmlessness, reduction, and resource recovery":

1. Reduction: Reduce the volume of waste by 80%-90% and the weight by more than 70%.

2. Harmlessness: Thoroughly decompose harmful organic substances in the waste (such as dioxins) through high temperatures, and effectively treat the flue gas generated by incineration to prevent secondary pollution.

3. Resource Recovery: Recover the heat generated from waste incineration for power generation or heating.

Mainstream Technology: Mechanical Grate Furnace Technology

Currently, the most mainstream and technologically mature municipal solid waste incineration technology internationally is the mechanical grate furnace technology. Its core principle is to allow waste to burn in a controlled, staged manner on a moving grate.

Below, we analyze its technical principles in detail along the journey of the waste:

Step One: Waste Pretreatment and Feeding

• Waste Reception and Storage: Garbage trucks transport municipal solid waste to the incineration plant and dump it into a large, sealed waste storage pit. The main functions of the storage pit are threefold:

◦ Mixing and Homogenization: Waste collected at different times varies in composition; mixing in the storage pit stabilizes the waste’s calorific value.

◦ Dehydration: Some moisture in the waste drains out, increasing the calorific value of the waste fed into the furnace.

•Fermentation: After a few days of storage, some organic matter ferments, making it easier to burn.

• Feeding System: A large waste crane grabs waste from the storage pit and deposits it into the feed hopper located at the top of the incinerator. Then, a pusher evenly and quantitatively pushes the waste into the furnace chamber.

Step Two: Core Combustion Process ("Three Ts and One E" Principle)

This is the core of the entire technology. Efficient combustion requires meeting the "Three Ts and One E" principle:

• Temperature: Maintain the furnace temperature above 850℃.

• Time: Flue gas residence time in the high-temperature zone is no less than 2 seconds.

• Turbulence: Stirring by combustion air ensures thorough mixing of waste and air.

• Excess Air: Provide more air than the theoretical amount to ensure complete combustion.

The mechanical grate furnace divides the combustion process into three zones, simulating an ideal combustion curve:

1. Drying Zone

◦ Location: Front section of the grate.

◦ Principle: Primary air (about 200℃) is supplied from beneath the grate to heat the waste, rapidly evaporating the moisture in the waste. The waste is dried, preparing it for ignition.

2. Combustion/Gasification Zone

◦ Location: Middle section of the grate.

◦ Principle: The dried waste begins pyrolysis and gasification under high-temperature radiation and the support of primary air, releasing a large amount of combustible gases (such as CO, H₂, CmHn, etc.). The solid part (mainly carbon) also starts intense combustion. This is the zone with the highest temperature and the most heat release.

3. Ashing Zone

◦ Location: Rear section of the grate.

◦ Principle: After the first two combustion stages, the waste has basically turned into ash. In this zone, the grate movement speed is slowed down to allow the residual carbon in the ash to fully combust, and the final slag is discharged from the slag outlet at the end of the grate.

Function of the Grate: The mechanical grate continuously stirs and transports the waste through complex movements (such as pushing and flipping), ensuring full contact between the waste and air to avoid combustion dead zones.

Step 3: Energy Recovery (Power Generation/Heating)

• The high-temperature flue gas (about 850-1000℃) generated by waste combustion flows upward into the boiler arranged above the furnace.

• The boiler consists of numerous pipes containing high-pressure water. The high-temperature flue gas transfers heat to the water pipes, heating the water into high-temperature, high-pressure steam.

• The steam is directed into the steam turbine generator set, where the steam drives the turbine blades to rotate, which in turn drives the generator to cut magnetic lines of force, generating electricity. The generated electricity is fed into the power grid. Some energy can also be used for district heating.

Step 4: Flue Gas Purification (Environmental Protection Key)

This is the core step to ensure the incineration plant meets environmental standards. Modern incineration plants adopt very strict "combined" purification processes, usually including:

1. Denitrification (removal of nitrogen oxides NOx):

◦ Technology: Selective Non-Catalytic Reduction (SNCR) or Selective Catalytic Reduction (SCR).

◦ Principle: Ammonia water or urea is sprayed into the furnace or specific catalyst areas to chemically react with NOx, producing harmless nitrogen gas (N₂) and water (H₂O).

2. Dust Removal (removal of particulates and heavy metals):

◦ Technology: Baghouse dust collector.

◦ Principle: Flue gas passes through a filtration device composed of countless fiber bags, where extremely fine dust particles (including heavy metals attached to them) are intercepted on the surface of the bags, and the purified flue gas is discharged.

3. Deacidification (removal of acidic gases: HCl, SOx, etc.):

◦ Technology: Dry/semi-dry injection of lime slurry + activated carbon adsorption.

Principle

■ Atomized lime slurry is injected to neutralize acidic gases in the flue gas.

■ Activated carbon is simultaneously injected, using its huge specific surface area to adsorb residual heavy metals, dioxins, and other hard-to-degrade organic pollutants in the flue gas.

◦ The reaction products and activated carbon powder adsorbing pollutants are ultimately captured by the subsequent baghouse dust collector.

After the above purification, the pollutant emission concentration in the flue gas is far below the country’s strictest environmental standards, and is finally safely discharged through the chimney.

Step 5: Ash and slag treatment

• Slag: Residue discharged from the end of the grate, an inert material, accounting for about 20%-30% of the original waste weight. After magnetic separation to recover metals, it is usually used for brick making, road paving, etc.

• Fly ash: Dust collected from the boiler and flue gas purification system (especially the baghouse dust collector), containing high concentrations of heavy metals and dioxins, is classified as hazardous waste. It must undergo stabilization/solidification treatment (such as cement solidification) before being sent to hazardous waste landfills for safe disposal.

Technology summary and advantages

Municipal solid waste incinerator technology, especially mechanical grate furnace technology, is a highly integrated system engineering. It successfully transforms troublesome “waste” into “energy” and achieves safe and environmentally friendly treatment.

Main advantages:

• Significant volume and weight reduction: one of the most effective methods to solve the “waste siege” problem.

• Energy recovery: turning waste into treasure, realizing resource recycling.

• Thorough harmlessness: high temperatures can completely eliminate pathogens and effectively decompose persistent organic pollutants such as dioxins.

• Land saving: greatly reduces land occupation compared to sanitary landfills.

• High treatment efficiency: suitable for handling large-scale urban municipal solid waste.

Of course, this technology also faces challenges, such as high initial investment, extremely high requirements for operation and management levels, and the need to address the “Not In My Backyard” (NIMBY) effect. However, through strict design, construction, and supervision, modern municipal solid waste incineration plants can fully become environmentally friendly municipal infrastructure coexisting with cities.