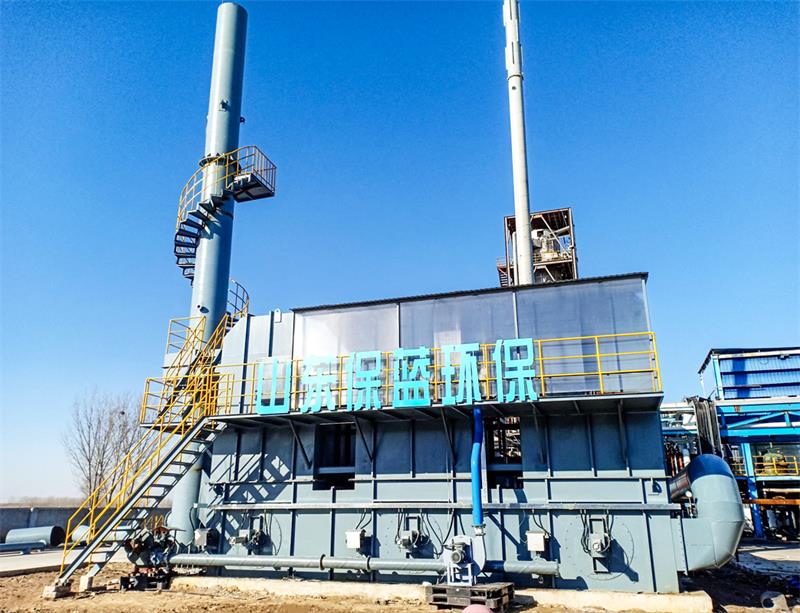

- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

- Product Details

Rotary Kiln

Technology Introduction

A rotary kiln is a large, long cylindrical thermal device. It slowly rotates the cylinder, allowing the material inside to move from the high end (feeding end) to the low end (discharge end) under the action of gravity, while fully exchanging heat with the hot gas flow, completing a series of physical and chemical changes.

Simply put, you can think of it as a slowly rotating, extra-long high-temperature furnace tube. It is a core piece of equipment in many industrial fields, especially in the building materials and metallurgical industries.

Working Principle

The technical principle of the rotary kiln can be summarized into the following key points:

1. Inclination and Rotation (Material Conveyance)

Inclined Installation: The kiln cylinder is installed on the support rollers with a slight inclination of 1.5% to 4%.

Slow Rotation: Driven by a motor and transmission device, the cylinder rotates slowly at a speed of 0.5 to 5 revolutions per minute.

Compound Motion: Due to the rotation and inclination of the cylinder, the material inside is lifted to a certain height along the cylinder wall and then slides down under gravity. This "lift-slide" process repeats cyclically, causing the material to move in a spiral path from the feeding end to the discharge end. This motion ensures thorough mixing and tumbling of the material.

2. Heat Exchange (Energy Transfer)

Counterflow Operation: The vast majority of rotary kilns use counterflow heat exchange. Material enters from the kiln tail (high end) and gradually moves toward the kiln head (low end); meanwhile, high-temperature gases (from the burner at the kiln head) flow from the kiln head toward the kiln tail.

Efficient Heat Transfer: This counterflow design allows the hottest flue gas to preheat the material about to enter the high-temperature zone, while the cooler material at the feeding end cools the flue gas about to be discharged, maximizing thermal energy utilization. The material is gradually heated during movement, undergoing drying, preheating, decomposition, calcination (or reduction), and cooling stages.

3. Physicochemical Changes (Process Objectives Realization)

Under suitable temperature and atmosphere, the material completes the required chemical reactions inside the kiln. For example:

Cement Kiln: Limestone (CaCO₃) decomposes into quicklime (CaO) and carbon dioxide (CO₂), then CaO reacts with SiO₂, Al₂O₃, Fe₂O₃ in clay to form cement clinker minerals (tricalcium silicate C₃S, dicalcium silicate C₂S, etc.).

Alumina Roasting Kiln: Aluminum hydroxide (Al(OH)₃) is roasted into alumina (Al₂O₃) suitable for electrolysis.

Metallurgical Kiln: Ore is oxidized or reduced roasted to remove impurities or change mineral forms, facilitating subsequent smelting.

Main Structural Components

A complete rotary kiln system mainly consists of the following parts:

1. Cylinder: A circular cylinder made by rolling and welding steel plates, serving as the main body of the rotary kiln. The interior is lined with refractory bricks (lining) to protect the cylinder from high-temperature erosion and material wear.

2. Tire (Riding Ring): A sturdy steel ring fitted around the cylinder. It transfers the entire kiln body’s weight to the supporting device.

3. Support Roller Device: Components that support the rolling ring and allow the rotary kiln shell to rotate. Usually, there are two support rollers in a set.

4. Transmission Device: Includes the main motor, reducer, pinion, and large gear ring. The large gear ring is fixed on the kiln shell and is driven to rotate by the pinion.

5. Support Device: Includes the base and bearings, used to support the support rollers.

6. Kiln Head Hood and Kiln Tail Hood: Located at both ends of the kiln, serving sealing and connecting functions. The kiln head hood connects the burner and feeding device, while the kiln tail hood connects the feeding equipment and flue gas treatment system (such as the preheater).

7. Burner (Nozzle): Installed at the kiln head, providing the heat required for the process. The fuel can be pulverized coal, natural gas, heavy oil, or industrial waste, etc.

8. Sealing Device: Installed at the interfaces between the kiln head hood and kiln tail hood and the rotary kiln shell, preventing outside cold air from entering and internal hot flue gas from leaking, ensuring a stable thermal regime inside the kiln.

Technical Advantages

Large Processing Capacity: Can continuously process a large amount of material, with high production efficiency.

Strong Adaptability: Can handle various forms of materials such as powder, granules, and blocks.

Stable Product Quality: Due to continuous tumbling of materials and uniform heating, product quality is stable.

High Thermal Efficiency: Especially modern rotary kilns with multi-stage preheaters, which make full use of thermal energy.

Can Handle Complex Reactions: By controlling temperature, atmosphere, and residence time, various processes such as calcination, reduction, oxidation, and chlorination can be completed.

Application Areas

Building Materials Industry:

Cement Production: This is the largest scale application of rotary kilns, used for the calcination of cement clinker.

Lime Production: Calcining limestone to produce quicklime.

Refractory Materials Production: Calcining high-alumina bauxite, magnesite, etc.

Metallurgical Industry:

Steel Industry: Producing pellet ore (chain grate - rotary kiln - ring cooler process).

Non-ferrous Metals: Oxidative roasting or reduction roasting of ores such as aluminum, zinc, tin, antimony, etc.

Chemical Industry:

Alumina Production: Roasting of aluminum hydroxide.

Production of chemical products such as chromium salts, barium salts, etc.

Environmental Protection Field:

Hazardous Waste Treatment: Utilizing the high temperature of rotary kilns (usually reaching above 1200℃) to thoroughly decompose toxic and harmful substances in waste, achieving harmless treatment.

Urban Sludge Incineration: Drying and incinerating sludge to achieve volume reduction and resource recovery.