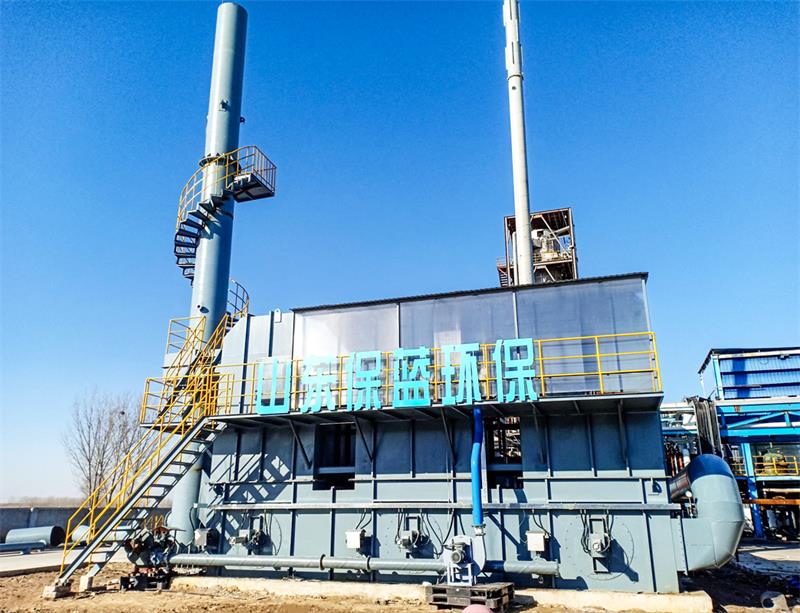

- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

- Product Details

Waste liquid Incinerator

Waste liquid incineration technology is a high-temperature thermal treatment technology, whose core objective is to completely decompose toxic, harmful, and organic waste liquids into harmless carbon dioxide, water vapor, and a small amount of stable solid residue through high-temperature oxidation, while recovering the heat generated during the process. It is one of the final disposal methods for hazardous waste treatment, especially suitable for high-concentration organic waste liquids that cannot be recycled or treated biochemically.

The following is a detailed breakdown of its technical principles:

I. Core Principle: High-Temperature Oxidation

The essence of waste liquid incineration is a vigorous oxidation reaction (combustion) process. Its basic chemical reaction formula can be expressed as:

Organic waste + O₂ → CO₂ + H₂O + Heat

To achieve this process completely and thoroughly, three basic conditions must be met, namely the “3T+E” principle:

1. Temperature: Maintain a sufficiently high furnace temperature, usually determined according to the thermal decomposition temperature of harmful components in the waste liquid, generally between 850°C and 1200°C. High temperature is a necessary condition to break the chemical bonds of organic molecules.

2. Time: The waste liquid and its combustion products must have sufficient residence time in the high-temperature zone to ensure complete reaction. The flue gas residence time is usually required to be no less than 2 seconds.

3. Turbulence: Through furnace design and the supply of combustion-supporting air, ensure thorough mixing of waste liquid, fuel, and air to form a turbulent state, guaranteeing that oxygen can fully contact and oxidize waste molecules.

4. Excess Air: Provide air slightly more than the theoretical oxygen demand (usually 20%-30% excess) to ensure sufficient oxygen for the oxidation reaction and avoid incomplete combustion products (such as carbon monoxide, black smoke, dioxins, etc.) caused by oxygen deficiency.

II. Main Components and Functions of the System

A complete waste liquid incineration system usually consists of the following core subsystems:

1. Waste Liquid Pretreatment and Feeding System

◦ Function: According to the physicochemical properties of the waste liquid (such as viscosity, calorific value, corrosiveness, solid content, etc.), homogenize, filter, dilute, or mix it to meet the feeding requirements of the incinerator.

◦ Key Equipment: Storage tanks, agitators, filters, pumps. The feeding device (such as screw pumps, high-pressure atomizing pumps) is crucial, requiring stable and precise delivery of waste liquid into the furnace.

2. Incinerator Body (Core)

◦ This is the core device where the combustion reaction occurs. According to the nature and scale of the waste liquid, the main types of furnaces are as follows:

◦ Rotary Kiln Incinerator:

■ Principle: A slightly inclined, slowly rotating cylindrical furnace. Waste liquid is injected from the high end, and as the kiln rotates, the waste liquid fully mixes with combustion-supporting air and moves forward, completing drying, combustion, and burnout processes.

■ Features: Highly adaptable, capable of handling solid, liquid, and gaseous wastes, especially suitable for waste liquids with high salt content or solid particles. However, the equipment is large and energy consumption is relatively high.

◦ Liquid Injection Incinerator:

■ Principle: The most classic waste liquid incinerator. Waste liquid is atomized into extremely fine droplets in the combustion chamber through an atomizing nozzle, greatly increasing the specific surface area, and rapidly burns after mixing with air.

■ Features: Relatively simple structure, high treatment efficiency, suitable for pumpable waste liquids with low solid content. The atomization effect is the key to combustion efficiency.

◦ Fluidized Bed Incinerator:

■ Principle: The furnace is filled with inert bed material (such as quartz sand). High-speed air introduced from the bottom causes the bed material to fluidize (similar to boiling liquid). Waste liquid is sprayed into the fluidized bed, where it violently collides and transfers heat with the high-temperature bed material, completing combustion instantly.

■ Features: Large heat capacity, stable combustion, high heat transfer efficiency, low nitrogen oxide emissions. However, it requires restrictions on the viscosity and solid content of the waste liquid and is not suitable for waste liquids prone to coking.

3. Combustion Support System

◦ Function: Provides the oxygen and initial heat required for combustion.

◦ Components: Combustion support fan, burners (main burner and auxiliary burner). The auxiliary burner is used when the waste liquid’s calorific value is insufficient or during furnace startup and shutdown to maintain furnace temperature.

4. Energy Recovery System (Optional)

◦ Function: Recovers heat from high-temperature flue gas to achieve energy utilization.

◦ Method: Typically, a waste heat boiler is installed at the flue gas outlet to generate steam for power generation or process heating, improving the overall system economy.

5. Flue Gas Purification System (Exhaust Gas Treatment System)

◦ Function: This is a key step to ensure emission compliance and environmental protection. High-temperature combustion produces flue gas containing acidic gases (HCl, SOx), heavy metals, dust, and potentially trace amounts of dioxins and other pollutants.

◦ Typical Process (Combined Technology):

■ Quench Tower: Rapidly cools flue gas from above 500°C to below 200°C within 1 second to prevent dioxin reformation.

■ Dry/Semi-Dry Acid Removal: Injects lime powder or lime slurry to neutralize acidic gases in the flue gas.

■ Bag Filter/Electrostatic Precipitator: Removes particulate matter (dust, heavy metal compounds, etc.) from the flue gas.

■ Wet Scrubber (Optional): Further deep removal of acidic gases.

■ SCR/SNCR (Optional): Used to remove nitrogen oxides (NOx).

■ Activated Carbon Adsorption (Optional): Sprays activated carbon powder to adsorb residual heavy metals and dioxins.

6. Automatic Control System

◦ Function: Using DCS or PLC systems to monitor and automatically adjust parameters such as temperature, pressure, flow rate, and oxygen content throughout the incineration process in real time, ensuring stable operation, safety, and compliant emissions.

Key Technical Points

1. Atomization Technology: For liquid injection furnaces, the performance of the atomizing nozzle directly determines combustion efficiency. Good atomization can produce micron-sized droplets, achieving rapid and complete combustion.

2. Dioxin Control: This is the difficulty and focus of waste liquid incineration technology. Control strategies include:

◦ In-furnace control: Maintain high temperature, sufficient oxygen, and long residence time to thoroughly decompose precursors.

◦ Tail-end control: Use a quench tower for rapid cooling to prevent re-synthesis.

3. Refractory Material Selection: The refractory lining of the incinerator must withstand high temperature, chemical corrosion, and thermal shock. Its selection directly affects furnace lifespan and operating costs.

4. Compatible Feeding: Scientifically blend waste liquids with different calorific values so that the mixed waste liquid’s calorific value remains stable within a suitable range (usually maintaining combustion without additional fuel), which can significantly reduce operating energy consumption.

Summary

Waste liquid incinerator technology is a complex system integrating chemical engineering, thermal engineering, mechanical engineering, automatic control, and environmental protection. Its basic principle is to use high-temperature oxidation to thoroughly decompose pollutants and ensure environmental safety through advanced flue gas treatment systems. This technology is an important means to achieve harmlessness, reduction, and resource recovery of hazardous waste liquids, widely applied in chemical, pharmaceutical, pesticide, refining, and other industries.