- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

- Product Details

Sodium Bicarbonate Desulfurization

Introduction

Dry sodium bicarbonate (NaHCO₃) desulfurization is an efficient flue gas desulfurization process, especially suitable for small and medium-sized boilers, waste incineration, glass kilns and other occasions. The core of the project is the reaction between the active sodium-based substances (Na₂CO₃ and Na₂O) produced by the thermal decomposition of sodium bicarbonate and SO₂ in the flue gas to achieve the removal of sulfur. Here's a detailed description of the process:

Process principle

Thermal decomposition reaction:

Sodium bicarbonate decomposes at 150-250°C into more active sodium carbonate (Na₂CO₃), water, and CO₂:

2NaHCO₃→Na₂CO₃+H₂O+CO₂

2NaHCO₃→Na₂CO₃+H₂O+CO₂

When further heated, Na₂CO₃ is converted to sodium oxide (Na₂O).

Desulfurization reaction:

The Na₂CO₃/Na₂O reacts with SO₂ and O₂ and H₂O in flue gas to form sodium sulfate (Na₂SO₄) and sodium sulfite (Na₂SO₃):

Na₂CO₃+SO₂+½O₂→Na₂SO₄+CO₂

Na₂CO₃+SO₂+½O₂→Na₂SO₄+CO₂

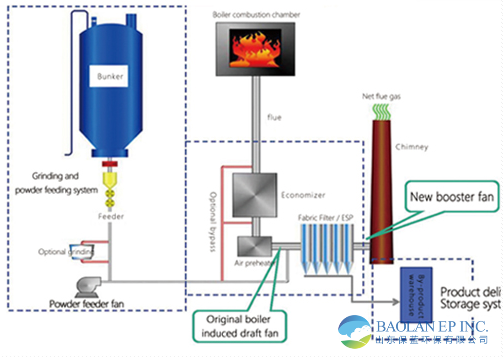

Process flow

Raw material pretreatment:

NaHCO₃ needs to be ground to a fine powder (usually 10-20 μm) to increase the specific surface area to improve the reaction efficiency.

If baking soda (commercial NaHCO₃) is used, it may need to be dried to avoid agglomeration.

Injection system:

The powder is sprayed into the flue by pneumatic conveying (usually in the flue section in front of the dust collector, temperature range 200-300°C).

The injection point needs to be optimized to ensure adequate mixing with the flue gas.

Reaction Section:

The flue gas is in full contact with the NaHCO₃ powder in the flue, SO₂ is absorbed, and the reaction time is ≥ 1 second.

Reaction efficiency can be improved by flue design, such as increased turbulence.

By-product collection:

The reaction products (Na₂SO₄, Na₂SO₃ and unreacted Na₂CO₃) are captured with flue gas entering the dust collector (such as bag dust collector).

By-products can be used as industrial raw materials (such as glass manufacturing) or safely landfilled.

Key process parameters

Reaction temperature: The optimal range is 140-250°C, too high will lead to sodium salt sintering and inactivation.

Stichiometric ratio: Typically the Na/S molar ratio is 1.5-2.0, ensuring efficient SO₂ removal (up to 95% or more).

Stay time: ≥ 1 second to ensure adequate response.

Flue gas humidity: An appropriate amount of moisture (5-10%) can promote the reaction, but too high can easily lead to equipment corrosion.

Advantage:

Simple equipment, no need for complex slurry systems, low investment.

It is suitable for renovation projects and occupies a small footprint.

Fast start-stop and suitable for intermittent operation conditions.

No wastewater is generated, and the by-products are dry and easy to treat.

Application scenarios

Industrial field: waste-to-energy incineration, glass kilns, ceramic kilns, biomass boilers, etc.

Applicable conditions: projects with medium and low sulfur coal flue gas, small flue gas volume or limited space.

Compare with other dry desulfurization

Comparison with limestone (CaCO₃) dry method:

NaHCO₃ is more reactive and has better desulfurization efficiency, but it is more costly.

Limestone requires higher temperatures (>800°C) and is suitable for circulating fluidized bed boilers.

Comparison with activated carbon adsorption:

Activated carbon can synergistically remove dioxins and heavy metals, but the regeneration is complex. The NaHCO₃ process is simpler.

Dry sodium bicarbonate desulfurization has become the preferred technology in specific scenarios due to its flexibility and efficiency, especially suitable for the treatment of small and medium-sized pollution sources in areas with strict restrictions on wastewater discharge.

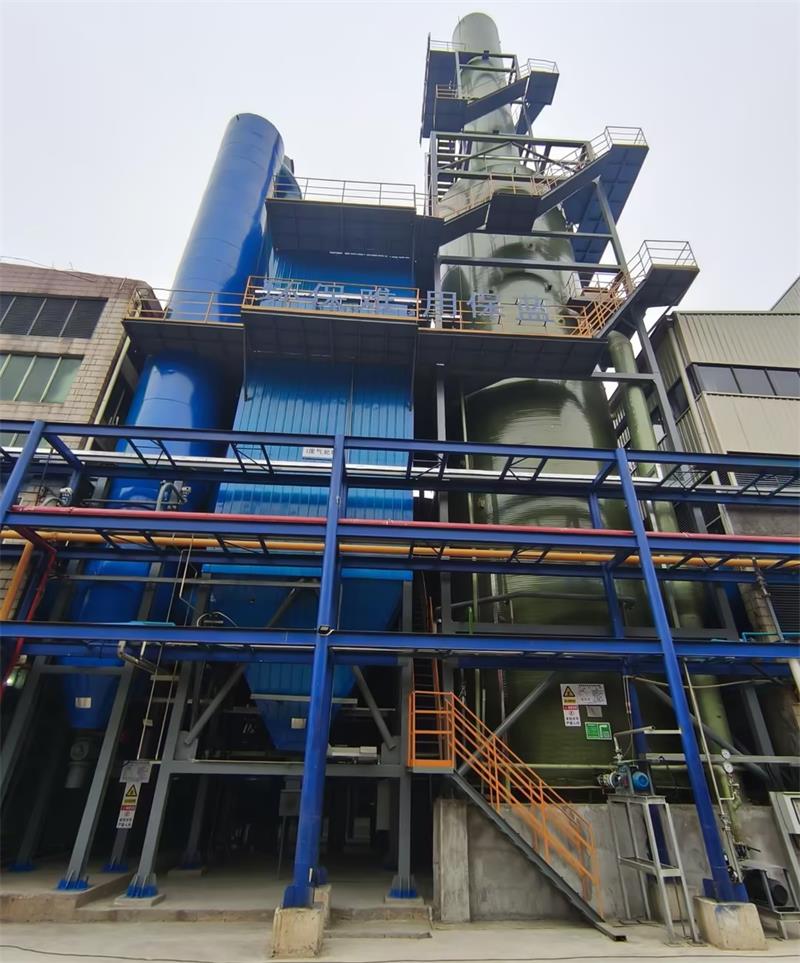

Project Case