- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

- Product Details

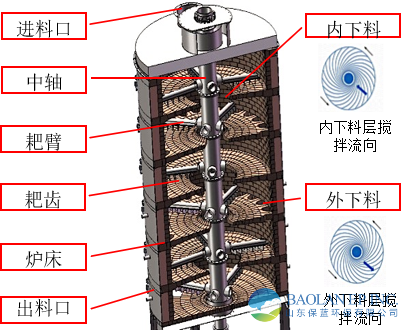

Multiple Hearth Furnace

Technology Introduction

Multiple Hearth Furnace is a continuous heat treatment equipment. Its core feature is that it is composed of multiple horizontal furnace chambers stacked vertically. Inside, materials are turned over layer by layer and conveyed downward through rotating shafts and rake arms, achieving a zoned and segmented heat treatment process

Product structure

1.Excellent sealing performance

The connection between the central shaft and the furnace chamber is sealed with water or sand to prevent the leakage of flammable gas inside the furnace.

High-temperature resistant double flap valves are installed at the feed port and discharge port.

The furnace door is installed closely to the furnace shell

2.Precise temperature control

Multiple burners can be installed on each floor for heating

Each burner has an independent valve group to control the ignition power

Precisely control the temperature range

The multi-stage furnace can operate at a maximum of 1150℃

3.The core stirring mechanism is stable and durable

The central shaft and the rake arm are forcibly cooled by the cooling fan to prevent deformation or damage due to overheating

Ensure a continuous supply of cooling air

Technical advantages

① Temperature stratified control

② Hierarchical control of atmosphere

③ Multiple operation modes

④ Low power consumption

⑤ Long service life

⑥ Excellent air tightness

⑦ Less heat energy loss

Application Areas

1.Regeneration of granular activated carbon

2.Production and manufacturing of granular activated carbon

3.Sludge drying/pyrolysis/incineration

4.Pyrolysis and recycling of waste lithium batteries

5.Pyrolysis of electronic waste

6.Oxidation/acidification roasting

7.Concentrate calcination

8.Steel Plant Dust and Sludge Recovery (D.R.I.

9.Vanadium slag recovery (SARU

10.Other fields