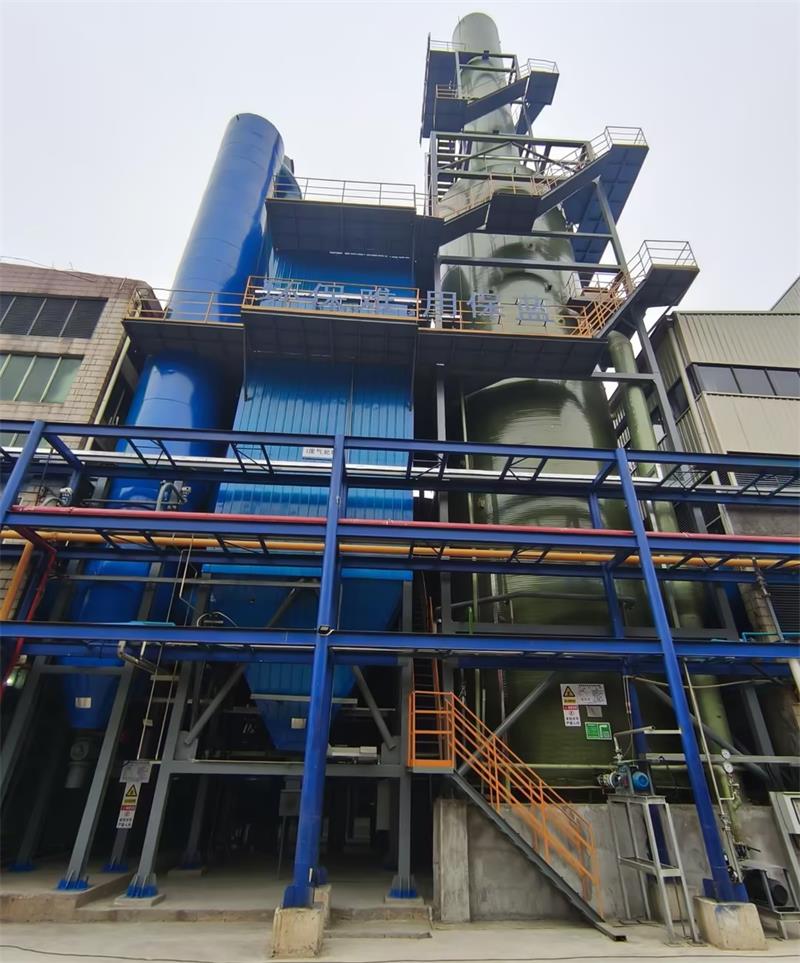

- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

- Product Details

Double Alkali Method Desulfurization

Introduction

The dual-alkali desulfurization method is a type of wet flue gas desulfurization technology that removes SO₂ from flue gas through staged reactions using two alkaline substances (usually sodium alkali and calcium alkali). It features both high desulfurization efficiency and low cost. Below is a detailed analysis of its process principles and characteristics:

Process Principles

Absorption Stage (mainly sodium alkali)

Flue gas enters the desulfurization tower and contacts the sprayed NaOH/Na₂CO₃ solution countercurrently, undergoing the following reactions:

SO₂+2NaOH→Na₂SO₃+H₂O

SO₂ + 2NaOH → Na₂SO₃ + H₂O

SO₂+Na₂CO₃→Na₂SO₃+CO₂↑

SO₂ + Na₂CO₃ → Na₂SO₃ + CO₂↑

Advantages: Sodium alkali has high solubility and fast absorption rate, suitable for high-efficiency desulfurization (efficiency can reach over 95%).

Regeneration Stage (calcium alkali precipitation)

The absorption liquid enters the regeneration tank, where lime (Ca(OH)₂) is added to regenerate sodium alkali and produce calcium sulfite/calcium sulfate precipitates:

Na₂SO₄ + Ca(OH)₂ → 2NaOH + CaSO₄↓

Advantages: Sodium alkali is recycled, reducing operating costs; by-products (gypsum) can be utilized as resources.

Oxidation Stage (optional)

Air is introduced to forcibly oxidize CaSO₃ to CaSO₄·2H₂O (gypsum), improving the purity of the by-product.

Key Design Parameters

pH control: Absorption tower pH 9-11 (sodium alkali), regeneration tank pH 10-12 (calcium alkali).

Liquid-to-gas ratio (L/G): 3-10 L/m³, adjusted according to SO₂ concentration.

Calcium-to-sulfur ratio (Ca/S): 1.05-1.1, ensuring complete regeneration.

Process Characteristics

Technical Advantages

High desulfurization efficiency: Sodium alkali absorbs quickly, suitable for treating high-sulfur flue gas (SO₂ concentration > 3000 mg/m³).

Low clogging risk: The absorption tower contains sodium-based clear liquid, avoiding scaling issues found in the limestone method.

Flexibility: Can adapt to load fluctuations by adjusting pH value and liquid-gas ratio.

Controllable by-products: Gypsum (CaSO₄) produced can be used in building materials, reducing solid waste disposal pressure.

Economics

Low operating cost: Sodium alkali is regenerated and recycled, only a small amount of loss needs to be replenished (about 5-10%).

Moderate investment: Equipment corrosion resistance requirements are lower than the ammonia method, but a regeneration system needs to be added.

Limitations

Sodium salt loss: Na⁺ is lost with wastewater or by-products, requiring continuous replenishment (e.g., using soda ash).

Sludge treatment: Requires sedimentation and dewatering equipment, increasing system complexity.

Calcium alkali purity requirements: Lime impurities may affect regeneration effectiveness.

Application scenarios

Small and medium boilers/sintering machines: Suitable for conditions with large sulfur load fluctuations.

Water-scarce areas: Compared to the limestone-gypsum method, water consumption is lower.

High sulfur coal flue gas: The high reactivity of sodium alkali ensures compliant emissions.

Summary

The dual alkali method balances efficiency and economy through the synergistic mechanism of "sodium alkali absorption - calcium alkali regeneration," especially suitable for small to medium flue gas treatment projects, but attention should be paid to sodium salt replenishment and sludge treatment issues.

Project Case