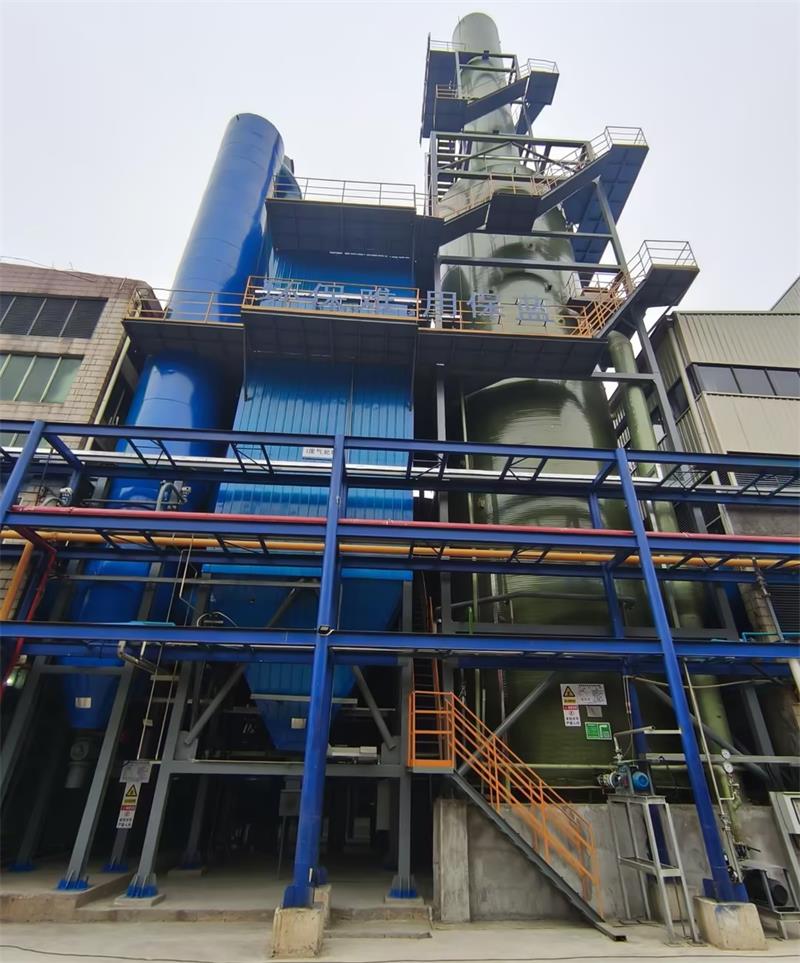

- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

- Product Details

Sodium Hydroxide Desulfurization

Introduction

The core principle of sodium hydroxide desulfurization technology is to use alkaline sodium hydroxide solution (or slurry) to absorb acidic sulfur dioxide gas, and generate stable sodium sulfite salt and water through acid-base neutralization reaction, so as to achieve the purpose of removing SO₂ from exhaust gas.

The essence of the whole process is a chemical absorption process.

Detailed chemical reaction mechanism

The process is mainly divided into two steps:

1. Absorption and neutralization (core reaction)

SO₂ in the exhaust gas comes into contact with sodium hydroxide lye, and the following neutralization reactions occur rapidly:

(Sodium hydroxide + sulfur dioxide → sodium sulfite + water)

This reaction rate is very fast and extremely efficient, and it is the main reaction for desulfurization.

2. Oxidation (subsequent treatment)

The resulting sodium sulfite (Na₂SO₃) is unstable in aqueous solution and has reducing properties. In order to facilitate the treatment and improve the stability of desulfurization by-products, air is usually forced into the absorption tower to oxidize sodium sulfite into stable sodium sulfate (Na₂SO₄, commonly known as Yuanming powder).

(Sodium sulfite + oxygen → Sodium sulfate)

Therefore, the final desulfurization byproduct is a sodium sulfate solution. The solution can be made into anhydrous sodium sulfate products for sale after subsequent concentration, crystallization, drying and other processes to achieve resource recycling.

Introduction to the process

A typical NaOH wet desulfurization system mainly consists of the following links:

1. Flue gas pretreatment: The high-temperature raw flue gas is first pretreated with dust removal (such as electrostatic precipitator) and cooling to meet the inlet requirements of the desulfurization tower.

2. Absorption process: The pretreated flue gas enters the absorption tower from the bottom (usually a spray empty tower or packing tower). Inside the tower, NaOH lye is ejected from top to bottom through the spray layer, forming a dense curtain. The flue gas is in contact with the lye counterflow, and sufficient gas-liquid mass transfer and chemical reaction occur, and SO₂ is efficiently absorbed.

3. Oxidation process: In the circulating slurry pool at the bottom of the absorption tower, the resulting sodium sulfite is forcibly oxidized to sodium sulfate by continuously blowing air through an oxidation fan.

4. By-product treatment: The concentration of sodium sulfate in the circulating slurry continues to rise, and part of it will be pumped out and sent to the by-product treatment system to generate high-purity sodium sulfate crystals through evaporation, crystallization, centrifugation, drying and other steps.

5. Flue gas reheating and discharge: After the purified low-temperature wet flue gas is removed by the mist eliminator to remove the water droplets, sometimes in order to improve the lifting height and diffusion effect of the flue gas, it will be heated by the flue gas reheater (GGH), and finally discharged through the chimney to meet the standard.

Technical characteristics

Advantage:

1. Extremely high desulfurization efficiency: usually up to 95% or even 99%, which can meet the most stringent emission standards.

2. Fast reaction speed: NaOH is a strong base that reacts very quickly with SO₂, and the volume of the absorption tower required is relatively small.

3. Simple system and high operation flexibility: The process flow is simpler than the limestone-gypsum method, and the adaptability to load changes is good.

4. No scaling and blockage problem: Compared with calcium desulfurization, the solubility of sodium salt generated by sodium-based desulfurization is very large, which basically avoids the risk of scaling and blockage in the tower and pipelines, and the system operation is more stable.

5. By-product value: By-product sodium sulfate is an important industrial raw material, which can be used to make pulp, glass, dyes, detergents, etc., and has certain economic value, which can achieve "waste treatment with waste".

Summary

Sodium hydroxide desulfurization technology is an efficient wet acid-base neutralization method. It takes advantage of the strong base of NaOH to quickly and efficiently absorb SO₂ and generate resource-resource-resourced sodium sulfate by-products through forced oxidation. Although it is expensive to operate due to its high sodium-alkali price, its extremely high desulfurization efficiency, stable operation without fouling, and valuable by-products make it an attractive choice in specific fields, especially in small and medium-sized flue gas treatment or when there is a demand for by-products.