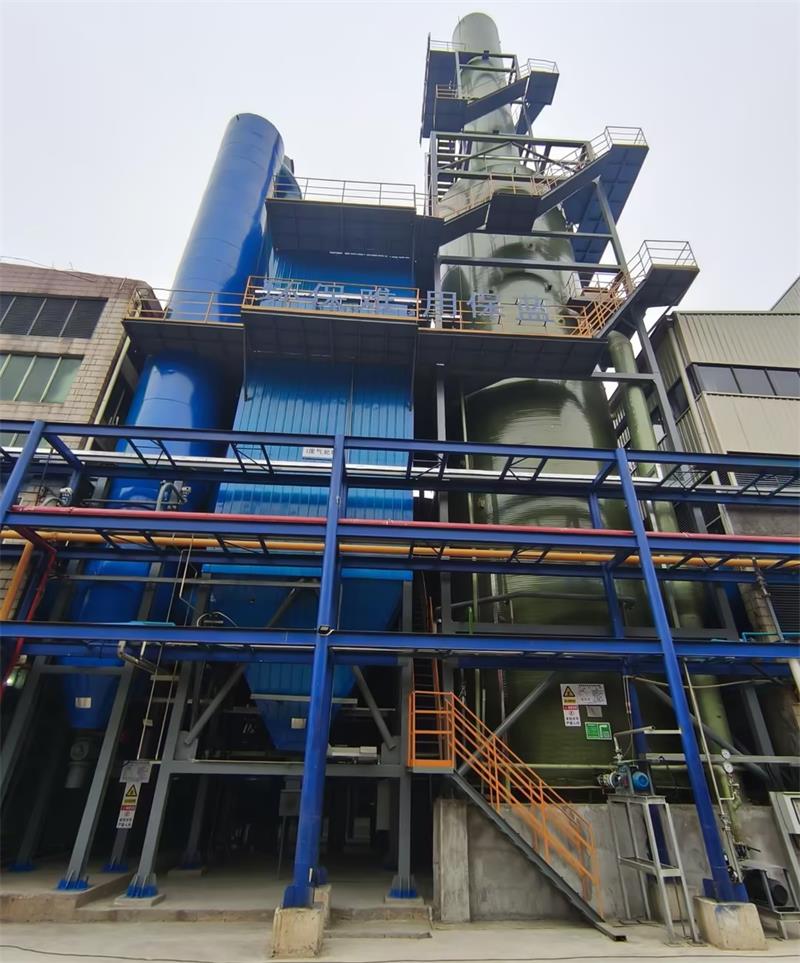

- Incinerator

- Waste Gas Treatment

- Environmental Monitoring

- Product Details

In-furnace Calcium Method Desulfurization

The in-furnace calcium method desulfurization is a common dry desulfurization technology, which is mainly used for the control of sulfur dioxide (SO₂) emissions from coal-fired boilers and industrial kilns. Its core principle is to desulfurize by spraying calcium-based absorbents (usually limestone or slaked lime) into the furnace or flue, reacting with SO₂ in the flue gas to form calcium sulfate.

Process principle

Main chemical reactions:

Limestone (CaCO₃) pyrolysis: decomposes into calcium oxide (CaO) and carbon dioxide (CO₂) at high temperatures.

CaCO₃→CaO+CO₂

CaCO₃→CaO+CO₂

SO₂ absorption: CaO reacts with SO₂ in flue gas to form calcium sulfate (CaSO₄).

CaO+SO₂+ ½O₂→CaSO₄

CaO+SO₂+ ½O₂→CaSO₄

If slaked lime (Ca(OH)₂ is sprayed, it reacts directly with SO₂:

Ca(OH)₂+SO₂→CaSO₃+H₂O

Ca(OH)₂+SO₂→CaSO₃+H₂O

(Subsequent oxidation to produce CaSO₄).

Process flow

In-Furnace Injection

Injection location: Spray powdered limestone (CaCO₃) or slaked lime (Ca(OH)₂) in the boiler combustion area (800–1200°C) or tail flue (500–600°C).

Reaction temperature: High temperature is conducive to limestone decomposition, but too high temperature (>1200°C) will lead to CaO sintering and reduce activity.

Key influencing factors

Calcium-sulfur ratio (Ca/S): Typically maintained at 2–3 (molar ratio), higher Ca/S increases desulfurization efficiency but increases absorbent consumption.

Reaction temperature: The optimal temperature is 800–950°C (inside the furnace) or 500–600°C (flue).

Absorbent particle size: The finer the particles, the larger the specific surface area, and the higher the reaction efficiency (generally requires a particle size of < 20μm).

Flue gas residence time: Extending the reaction time can improve the SO₂ absorption rate.

Advantages

Simple equipment: no need for complex wet systems, low investment and operating costs.

No wastewater generation: The dry process avoids wastewater treatment problems.

Wide applicability: It can be used to retrofit existing boilers, especially for low-sulfur coal (<2% sulfur content).

Summary

The in-furnace calcium method desulfurization is an economical and practical dry desulfurization technology, which is suitable for small and medium-sized boilers or low-sulfur coal scenarios, but it needs to be combined with auxiliary measures such as humidification and activation according to specific needs. For high-sulfur coal or strict emission standards, wet or other efficient desulfurization processes still need to be considered.

Project Case